Fuses Definition:

Fuses Definition States that : A fuses is a short piece of metal, inserted in the circuit, which melts when excessive current flows through it and thus breaks the circuit.

The fuse element is generally made of materials having low melting point, high conductivity and least deterioration due to oxidation e.g., silver copper etc. It is inserted in series with the circuit to be protected. Under normal operating conditions, the fuse element is at a temperature below its melting point. Therefore, it carries the normal current without overheating. However, when a short-circuit or overload occurs, the current through the fuse increases beyond its rated value. This raises the temperature and fuse element melts (or blows out), disconnecting the circuit protected by it. In this way, a fuse protects the machines and equipment from damage due to excessive currents.

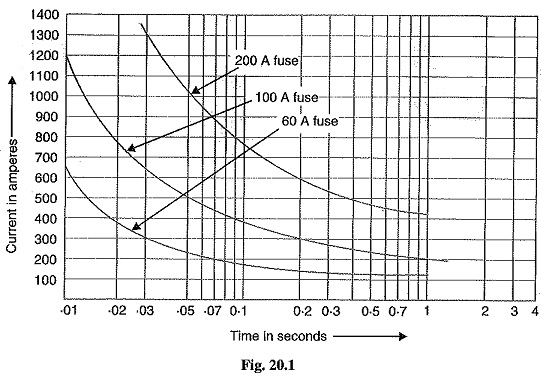

The time required to blow out the fuse depends upon the magnitude of excessive current. The greater the current, the smaller is the time taken by the fuse to blow out. In other words, a fuse has inverse time-current characteristics as shown in Fig. 20.1. Such a characteristic permits its use for over current protection.

Advantages

- It is the cheapest form of protection available.

- It requires no maintenance.

- Its operation is inherently completely automatic unlike a circuit breaker which requires an elaborate equipment for automatic action.

- It can break heavy short-circuit currents without noise or smoke.

- The smaller sizes of fuse element impose a current limiting effect under short-circuit conditions.

- The inverse time-current characteristic of a Fuses Definition makes it suitable for over current protection.

- The minimum time of operation can be made much shorter than with the circuit breakers.

Disadvantages

- Considerable time is lost in rewiring or replacing a fuse after operation.

- On heavy short-circuits, discrimination between fuses in series cannot be obtained unless there is sufficient difference in the sizes of the Fuses Definition concerned.

- The current-time characteristic of a fuse cannot always be co-related with that of the protected apparatus.

Characteristics of Fuse Element:

The function of a fuse is to carry the normal current without overheating but when the current exceeds its normal value, it rapidly heats up to melting point and disconnects the circuit protected by it. In order that it may perform this function satisfactorily, the fuse element should have the following desirable characteristics :

- low melting point e.g., tin, lead.

- high conductivity e.g., silver, copper.

- free from deterioration due to oxidation e.g., silver

- low cost e.g., lead, tin, copper.

The above discussion reveals that no material possesses all the characteristics. For instance, lead has low melting point but it has high specific resistance and is liable to oxidation. Similarly, copper has high conductivity and low cost but oxidizes rapidly. Therefore, a compromise is made in the selection of material for a Fuses Definition.

Fuse Element Materials:

The most commonly used materials for fuse element are lead, tin, copper, zinc and silver. For small currents up to 10 A, tin or all alloy of lead and tin (lead 37%, tin 63%) is used for making the fuse element. For larger currents, copper or silver is employed. It is a usual practice to tin the copper to protect it from oxidation. Zinc (in strip form only) is good if a Fuses Definition with considerable time-lag is required i.e., one which does not melt very quickly with a small overload.

The present trend is to use silver despite its high cost due to the following reasons :

- It is comparatively free from oxidation.

- It does not deteriorate when used in dry air.

- The coefficient of expansion of silver is so small that no critical fatigue occurs. Therefore, the fuse element can carry the rated current continuously for a long time.

- The conductivity of silver is very high. Therefore, for a given rating of fuse element, the mass of silver metal required is smaller than that of other materials. This minimizes the problem of clearing the mass of vaporized material set free on fusion and thus permits fast operating speed.

- Due to comparatively low specific heat, silver fusible elements can be raised from normal temperature to vaporization quicker than other fusible elements. Moreover, the resistance of silver increases abruptly as the melting temperature is reached, thus making the transition from melting to vaporization almost instantaneous. Consequently, operation becomes very much faster at higher

- Silver vaporizes at a temperature much lower than the one at which its vapour will readily Therefore, when an arc is formed through the vaporized portion of the element, the arc path has high resistance. As a result, short-circuit current is quickly interrupted.

Important Terms in Fuses

The following terms are much used in the analysis of fuses :

- Current rating of fuse element: It is the current which the fuse element can normally carry without overheating or It depends upon the temperature rise of the contacts of the fuse holder, fuse material and the surroundings of the Fuses Definition.

- Fusing current: It is the minimum current at which the fuse element melts and thus disconnects the circuit protected by it. Obviously, its value will be more than the current rating of the fuse element.

For a round wire, the approximate relationship between fusing current I and diameter d of the wire is

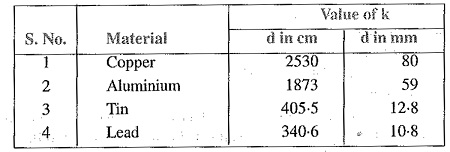

where k is a constant, called the fuse constant. Its value depends upon the metal of which the fuse element is made. Sir W.H. Preece found the value of k for different materials as given in the table below :

The fusing current depends upon the various factors such as :

- material of fuse element

- length — the smaller the length, the greater the current because a short fuse can easily conduct away all the heat

- diameter

- size and location of terminals

- previous history

- type of enclosure used

- Fusing factor: It is the ratio of minimum fusing current to the current rating of the fuse element i.e.

Its value is always more than one. The smaller the fusing factor, the greater is the difficulty in avoiding deterioration due to overheating and oxidation at rated carrying current. For a semi-enclosed or rewirable Fuses Definition which employs copper wire as the fuse element, the fusing factor is usually 2. Lower values of fusing factor can be employed for enclosed type cartridge fuses using silver or bimetallic elements.

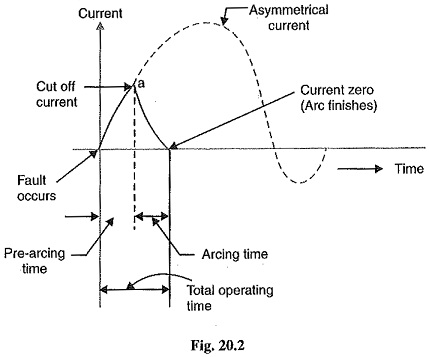

- Prospective Current: Fig. 20.2 shows how a.c. current is cut off by a fuse. The fault current would normally have a very large first loop, but it actually generates sufficient energy to melt the fuseable element well before the peak of this first loop is reached. The r.m.s. value of the first loop of fault current is known as prospective current. Therefore, prospective current can be defined as under:

It is the r.m.s. value of the first loop of the fault current obtained if the fuse is replaced by an ordinary conductor of negligible resistance.

- Cut-off current: It is the maximum value of fault current actually reached before the fuse melts.

On the occurrence of a fault, the fault current has a very large first loop due to a fair degree of asymmetry. The heat generated is sufficient to melt the fuse element well before the peak of first loop is reached (point ‘a’ in Fig. 20.2). The current corresponding to point ‘a’ is the cut off current. The cut off value depends upon

- current rating of fuse

- value of prospective current

- asymmetry of short-circuit current

It may be mentioned here that outstanding feature of fuse action is the breaking of circuit before the fault current reaches its first peak. This gives the Fuses Definition a great advantage over a circuit breaker since the most severe thermal and electro-magnetic effects of short-circuit currents (which occur at the peak value of prospective current) are not experienced with fuses. Therefore, the circuits protected by fuses can be designed to withstand maximum current equal to the cut-off value. This consideration together with the relative cheapness of fuses allows much saving in cost.

- Pre-arcing time: It is the time between the commencement of fault and the instant when cut off occurs.

When a fault occurs, the fault current rises rapidly and generates heat in the fuse element. As the fault current reaches the cut off value, the fuse element melts and an arc in initiated. The time from the start of the fault to the instant the arc is initiated is known as pre-arcing time. The pre-arcing time is generally small : a typical value being 0.001 second

- Arcing time: This is the time between the end of pre-arcing time and the instant when the arc is extinguished.

- Total operating time: It is the sum of pre-arcing and arcing times.

It may be noted that operating time of a fuse is generally quite low (say 0.002 sec.) as compared to a circuit breaker (say 0.2 sec or so). This is an added advantage of a fuse over a circuit breaker. A fuse in series with a circuit breaker of low-breaking capacity is a useful and economical arrangement to provide adequate short-circuit protection. It is because the fuse will blow under fault conditions before the circuit breaker has the time to operate.

- Breaking capacity: It is the r.m.s. value of a.c. component of maximum prospective current that a fuse can deal with at rated service voltage.