Stroboscope Working Principle:

The stroboscope working principle uses a high intensity light which flashes at precise intervals. This light may be directed upon a rotating or vibrating object. The stroboscopic effect is apparent when the rotational or vibratory speed is in a proper ratio with the frequency of the light flashes.

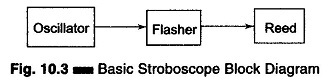

Most stroboscope working principle consist of an oscillator, a reed, and a flasher, as illustrated in Fig. 10.3. The oscillator provides trigger pulses to the flasher mechanism to control the flashing rate. The oscillator is generally an externally triggered multivibrator. The vibrating reed serves as a reference for accurately calibrating the stroboscope. The reed is driven from the ac lines and vibrates at 7200 times per minute. This steady rate is used to standardise the calibration scale over a narrow range. The flasher produces the illumination for the measurements.

The flasher tube is fired by a capacitor discharge, which is, in turn, controlled by trigger pulses from the oscillator. The tube is filled with a suitable inert gas which produces light when it is ionised. The tube life ranges from 200 to 1000 hours, depending upon the operating conditions.

When the frequency of movement exactly matches the stroboscope frequency, the moving object is viewed clearly only once during each revolution. This causes the moving object to appear as a single stationary image. A stationary image also appears when the speed of rotation is some exact multiple of the stroboscope frequency. The highest scale reading that produces the single, still image is the fundamental frequency.

Multiple still images appear when the stroboscope frequency is some multiple of the rotation frequency. In this case the light flashes more than once during each rotation of the object. (The radial line at the end of the shaft may appear as several equally spaced lines. If lamp frequency is twice the rotational frequency, two images are produced, 180° apart. If the lamp frequency is three times the rotational frequency, three images appear, each at a spacing of 120°.)

Moving images are obtained when the light frequency and rotational frequency are not synchronised. When the image appears to rotate in a direction opposite to that of actual rotation, the rotation frequency is less than the flasher frequency. When it appears to rotate in the same direction as the actual rotation, the rotation frequency is higher than the flasher frequency.

A stroboscope working principle may be used to check motor or generator speeds ranging from 60 to 1,000,000 rpm. The stroboscope is highly versatile, uses no power from the circuit being measured and when calibrated, has an accuracy as close as 0.1%. (Some scopes, use the line frequency for calibration. The flash lamp and reflector assembly rotates 360° for maximum flexibility. The case may be mounted on a tripod. The flash rate is 110 to 150,000 flashes per minute, enabling measuring speeds of up to 1,000,000 rpm. The light output varies with the flash rate, from 3 μs to 0.5 μs.)