Repulsion Start Induction Motor – Working Principle:

As the name implies, the repulsion-start induction motor starts as a repulsion motor and runs as an induction motor.

The general construction of a repulsion-start induction motor is quite similar to that of a repulsion motor (i.e., a laminated stator core complete with one winding similar to the main winding of a split-phase motor and a rotor, also called the armature, consisting of slots in which a winding is placed and connected to a commutator). The only difference is that in addition to the basic repulsion-motor construction it is equipped with a centrifugal device which operates at about 75-80 per cent of synchronous speed and short circuits all of the commutator segments.

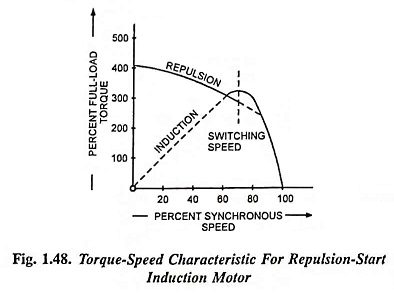

The repulsion-start induction motor combines the desirable starting characteristics of the repulsion motor (i.e., high starting torque with moderate starting current) with operating characteristic (constant speed running) of the induction motor. A typical performance characteristic of a repulsion-start induction motor is given in Fig. 1.48. The starting torque is 3 to 6 times of full-load torque, and the starting current is approximately 3-4 times of full-load current.

The direction of rotation of such a motor may be reversed by shifting the brushes, but the brush rigging is not readily accessible, and the method is poorer than with any of the capacitor type motors.

The efficiency and the maximum operating torque of the repulsion-start induction motor are usually less than those of a squirrel cage induction motor of comparative size i.e., a repulsion-start induction motor must be larger than a squirrel cage motor of the same rating to give the same performance.

As compared to capacitor motors, these motors (i) need more maintenance because of commutator, brushes and centrifugal switch, (ii) are relatively more expensive, (iii) cause radio interference during starting, and (iv) are noiser, especially when the brushes continue to ride on commutator.

However, despite all the drawbacks, these motors are still used in integral kilowatt ratings because they (i) develop higher starting torque with low starting current and (ii) can withstand longer starting periods than capacitor type motors.

Such motors are suitable for commercial refrigerators, compressors, pumps, hoists and other constant speed drives, particularly those which have a high inertia and prolonged starting period. The usual rating is from 1/3 kW to 12 kW but for special applications, ratings as high as 30 kW are available.