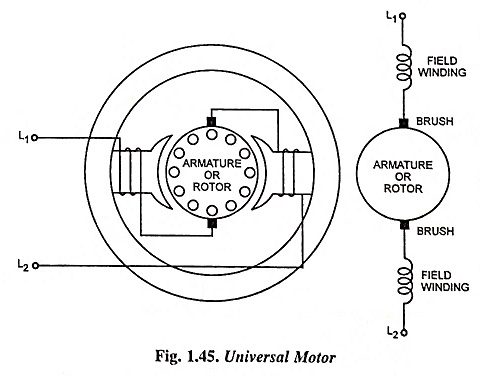

Universal Motor – Construction, Working Principle and Applications:

A universal motor is a specifically designed series wound motor, that operates at approximately the same speed and output on either dc or ac of approximately same voltage. Because of the difficulty in obtaining like performance on dc and ac at low speeds, most universal motors are designed to operate at speeds exceeding 3,500 rpm. Motors operating at speeds 8,000 to 10,000 rpm are common.

Universal motor is constructed with few series field turns, laminated armature and field circuits, low-reluctance magnetic path, increased armature conductors and commutator segments and using low flux densities so as to minimize the adverse effects caused by high field reactances, eddy current and hysteresis losses.

Universal motors may be either compensated (distributed field) or uncompensated (concentrated field) type, the latter type being used for higher speeds and smaller output ratings (usually not exceeding 200 W) only.

The speed-torque characteristic of a universal motor is quite similar to that of a series wound dc motor, i.e., high starting torque and high no-load speed. Universal motors beings high speed motors, are smaller in size and lighter in weight as compared to other motors of the same output. Full-load pf is high (approximately 0.9) but it is poor at start and on overloads. The direction of rotation of any series motor can be reversed by reversing the direction of flow of current in either the field or armature circuit (but not through both). The speed of universal motor, for any given load, can be changed by changing either flux or applied voltage or both.

Applications:

Very small power output rating universal motors, which usually do not exceed 5 or 10 watts are employed in such equipment as sewing machines, fans, portable hand tools, hair dryers, motion-picture projectors, and electric shavers. The higher rating (5-500 W) universal motors are used in vacuum cleaners, electric typewriters, food mixers and blenders, motion-picture projectors, cameras, adding machines, and calculating machines.

The small series motors are frequently furnished as motor parts, i.e., consisting of bare stators and rotors (with shaft) but without bearings or feet. They can then be compactly “built in” to the power using devices.