Ultrasonic Welding Working Principle and Applications:

Ultrasonic welding is a solid state welding process that produces coalescence of materials by the local application of high-frequency (20-60 kHz) vibratory energy as the workpieces are held together under pressure. No flux or filler metals are used, no electrical current flows through the weld metal, and usually no heat is applied. Since vibratory action in ultrasonic welding breaks up and disperses moisture, oxide and other (e.g., insulation) coatings, normally, degreasing may be the only cleaning required before welding (especially with aluminium).

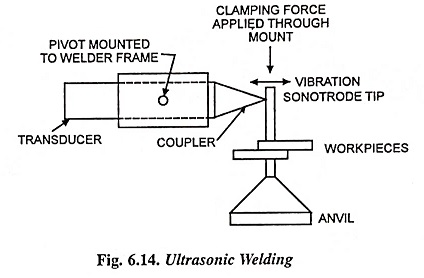

Welding occurs when the ultrasonic tip or electrode, the energy coupling device, is clamped against the workpieces and is made to oscillate in a plane parallel to the weld interface. The combined clamping pressure and oscillating forces introduce dynamic stresses in the base metal. This produces minute deformations which create a moderate temperature rise in the base metal at the weld zone. This coupled with the clamping pressure provides for coalescence across the interface to produce the weld.

Ultrasonic energy will aid in cleaning the weld area by breaking up oxide films and causing them to be carried away. The vibratory energy that produces the minute deformation comes from a transducer which converts high-frequency alternating electrical energy into mechanical energy. The transducer is coupled to the work by various types of tooling which can range from tips similar to resistance welding tips to resistance roll welding electrode wheels.

The temperature at the weld is not raised to the melting point and, therefore, there is no nugget similar to resistance welding. Weld strength is equal to the strength of the base metal. Most ductile metals can be welded together and there are many combinations of dissimilar metals that can be welded. The process is restricted to relatively thin materials normally in the foil or extremely thin gauge thicknesses. The maximum thickness by these processes ultrasonically may vary from 0.38 to 2.5 mm depending upon the metal.

Applications:

This Ultrasonic welding process is used extensively in the electronics, aerospace, and instrument industries. It is also used for producing packages and containers and for sealing them. The process can also be employed for joining plastics and is finding wider use in this field than in joining metals.