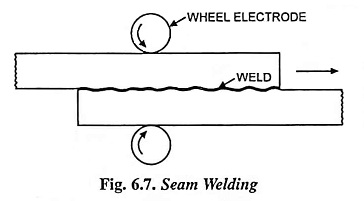

Seam Welding – Definition and Working Principle:

Definition – Seam welding can be defined as series of continuous spot welds. This process is employed for making a continuous joint between two overlapping pieces of sheet metal.

Working Principle:

In this process the work to be welded is placed between the two wheels which apply sufficient mechanical pressure and also carry sufficient current for producing continuous welds. The mechanical pressure applied is kept constant and the current is regulated by a timer (the current is kept on for a definite time and then off for another fixed interval).

As the pressure is applied, the drive is started, the welding current switched on and simultaneously the overlapping surfaces of the metal are forced together as fast as they are heated. The heat is generated due to flow of current through the resistance in the welding circuit. The heat generated can be controlled by either varying the current or pressure between the sheets which varies the contact resistance. If the rate of heat generation is high then the speed of the rollers is increased thereby reducing the welding time and vice versa.

The electrodes are made of copper alloys and are water circulated in order to dissipate heat from them. In high speed seam welding using continuous current the frequency of the current acts as an interrupter. In order to localise the current and pressure to the welding point, the contact area of the electrodes is kept small. Usually number of spots obtained per metre of the joint are between 200 and 400 depending upon the nature of the joint required. Welding speed ranges from 0.25 metre to 10 metres per minute. This type of welding is very important as it provides pressure tight or leak proof joint.

It is very essential in case of seam welding that the surfaces to be welded are cleaned and made dust and dirt free. This is not necessary in other forms of resistance welding, e.g., in spot welding the detrimental effect of scale and surface dirt can be compensated for by adjustment of time, pressure, current or by other means but this is not true of seam welding.

Materials which can be seam welded after they are cleaned include high-carbon, stainless and coated steels and alloys of aluminium, nickel and magnesium. Seam welding of copper and high copper alloys is not recommended. Seam welding is employed for welding pipes, conduits, tanks, transformers, refrigerators, gasoline tanks, aircrafts and various types of containers. This process is best adopted for metal thickness ranging from 0.25 mm to 3 mm.