Laser Beam Welding – Definition, Block Diagram and Workings:

Laser beam welding is a welding process that uses the heat from a laser beam impinging on the joint. The process is used without a shielding gas and without the application of pressure. The laser is a device that produces a concentrated coherent light beam by stimulating electronic or molecular transitions to lower energy levels. The word laser is an acronym for “light amplification by stimulated emission of radiation“. The laser beam is a highly concentrated source of energy which has many applications. It can be used for welding, for cutting metals and non-metals, for surface heat treating of metals, and for cladding by fusing powders to base materials. It can also be used for brazing and soldering, and for drilling, machining, and marking. It is also used in other fields : medicine, communications, marking and surveying.

There are two basic types of lasers employed in metal working. The original types are the solid state lasers, which use a solid sodium. The second type are the gas lasers, which normally use a mixture of helium, nitrogen, and CO2 gas in a tube. In either case, when the medium is excited, it emits photons, which become the laser beam.

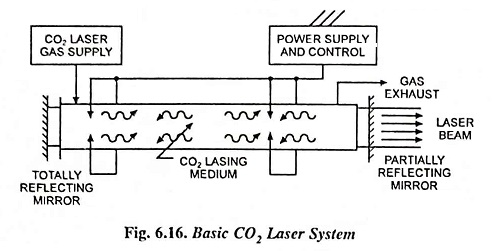

A gas laser beam is shown in Fig. 6.16. Excitation of gas laser is by means of high-voltage low-current electric power. The electrical discharge excites the CO2 molecules, which on returning to their original state, emit photons. Mirrors are placed on both ends of the tube, one entirely reflective and the other with small partially transmissive area to permit the beam to exit. This forms a cavity in which photons builds up. The freed photons travel between the mirrors and excite the CO2 molecules, starting a chain reaction of photon emissions. A stream of photons, the laser beam, exits through the unsilvered section of the one mirror. The wavelength of the laser beam is 10.6 μm. This wavelength is longer and does not have the safety problems of the short wavelength beam. The CO2 gas lasers can be operated in the continuous wave mode or in the pulsed mode.

There are several types of CO2 lasers. The early or low powered type used a “sealed tube” which has a power output of from 3 to 100 W. The axial flow type, which is more complex method of producing laser beams, will produce from 50 to 2,000 W average output power. Another type, known as the transverse flow type, has an average output power of from 2 to 15 kW. The laser power supply system is called an oscillator. These different types of CO2 lasers involve different designs of the beam-producing apparatus. The size of the apparatus and the efficiency of the system are different.

The laser beam is very intense and unidirectional but can be focused and reflected in the same way as an ordinary light beam. The focus size is controlled by the choice of lenses and mirrors and the distance to the workpiece. The spot size can be made as small as 1 mm to up to 12 mm. The smaller focus spot size is used for cutting and welding, and the larger spot size is used for heat treating. The laser beam can be used in open air and can be transmitted long distances with only minimal loss of power.

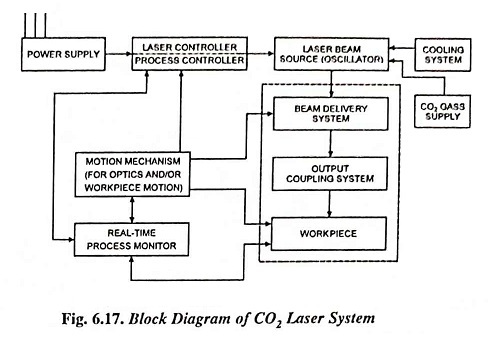

A block diagram of a laser beam welding system is shown in Fig. 6.17. This shows the major components.

When using a laser beam for welding, the beam impinges on the surface of the base metal with such a concentration of energy that the surface is melted and volatilized. When the metal is raised to its melting temperature, the surface conditions have a minor effect on reflecting the beam. The distance from the optical cavity to the workpiece has little effect on the laser, because it can be focused to the proper spot size at the work with the same amount of energy available whether it is close or far away.

With laser beam welding the molten metal takes on a radial configuration similar to plasma arc welding, known as “melt-in” welding. When the power density rises above a certain threshold level, keyholing occurs, the same as with plasma arc or electron beam welding. Keyholing provides for extremely deep penetration, which provides the weld a high depth-to-width ratio. For some applications, inert gas is used to shield the molten metal from the atmosphere.

The welding characteristics of the laser are similar to those of the electron beam. The laser can weld the same joint types. The concentration of energy by both beams is similar, with the laser having a power density of the order of 106W/cm2. The power density of electron beam is slightly greater.

The location of the focal point of the beam with respect to the surface of the workpiece is important. Maximum penetration occurs when the beam is focused slightly below the surface. Penetration is less when the beam is focused on the surface or deep within the surface. As the power is increased, the depth of penetration increases.

Advantages and Disadvantages:

Heating and cooling rates are much higher in laser beam welding than in arc welding, and the heat-affected zones are much smaller. Rapid cooling rates can create problems, such a cracking in high-carbon steels.

Applications:

The laser beam has been used to weld carbon steels, high-strength low-alloy steels, aluminium, stainless steel, and titanium. Laser welds are similar in quality to welds made by electron beam process. Filler metal is used to weld metals that tend to show porosity when welded with either electron beam or laser beam welding.

Materials 12 mm thick are being welded at a speed of 250 mm per minute. The efficiency of laser beam welding equipment is 5 to 10%, but as new equipment becomes available this will increase. The cost of the equipment will decrease in the future. More welding applications for laser welding are being found daily, and its use will increase.