Projection Welding – Definition, Working, Advantages and Applications:

Projection welding is a resistance welding process that produces coalescence by the heat obtained from the resistance to the flow of the welding current. The resulting welds are localized at predetermined points by projections, embossments or intersections.

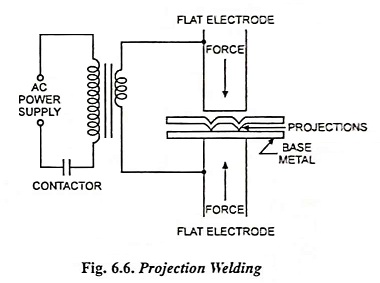

Projection welding uses the same equipment as spot welding. The only difference is that the electrodes used are flat on the ends and larger in diameter than the flat electrodes used in spot welding. Successful projection welding depends greatly on the surface preparation of the pieces to be welded. Projections, small deformations that will touch the surface of the material to be welded, are made on the weld areas. One of the main advantages of these projected points is that welding area can be located easily, which makes projection welding a high-production welding technique. As the current flows through the two parts to be welded, the projected points are the main contact area. Whenever a point or projection touches the metal, a weld nugget will start. These weld points soon reach the plastic state, and the force applied by the electrodes finishes the weld nugget. The cycle time is the same as the spot-weld time. As the points reach their plastic state, the metal is compressed so that the finished weld is similar to the spot weld with the exception of the small indentations created by projections.

Projection welding, as spot welding, needs no protective atmosphere in order to produce successful results. It is also useful in securing small circular component, to larger pieces of metal. For projection weldings, a large flat-surfaced electrode is used, which covers the areas of the projections. The areas of projection, one or more, and the spots where they touch on the other piece of metal will be the only places where fusion takes place, even with a large electrode. Projection welding has been used by auto manufacturers for many years. Auto bodies have many areas that are projection welded. Another area that uses projection welding is stud welding, which has also been utilized for car bodies.

Projection welding reduces the amount of current and pressure required in order to form a good bond between two surfaces. With this reduction there is less chance of shrinkage and distortion in the areas surrounding the weld zone, one reason why it has been incorporated into many manufacturing processes.

Projection welding has the following advantages over spot welding :

- Projection makes the welding process simple.

- It is possible to join several welding points in projection welding.

- More output is obtained since more than one weld are done at a time.

- Electrode life is increased due to use of low current density and low pressure.

- Good finished appearance is obtained as surface remains unidented by the electrodes.

- Welds are automatically located by the position of projections.

- As the electrodes are flat, therefore the contact area over the projection is sufficient. It facilitates the easier maintenance of electrodes, alignments of parts and construction of various jigs and fixtures.

- With the projection welding, it is easy to weld certain parts which cannot be welded by spot welding.

When the two plates to be welded are of different cross-sectional area then in order to obtain desirable strength it becomes necessary to have the projections on the thicker plate.

When the two plates to be welded are of different material then the projections should be made on the high conductivity materials.

The thickness of plates to be jointed is limited to 2 x 6 mm in case of steel, 2 x 4 mm in case of aluminium, and 2 x 2 mm in case of copper. This reduction in maximum thickness of different metals is due to increase in conductivity.

The initial cost of the equipment required for projection welding is high as press type machines are required for this type of welding.

This type of welding is usually employed on punched, formed or stamped parts, where the projections automatically exist.

Small fasteners, nuts etc. can be welded to larger components.

Projection welding is particularly applicable to mass production work, e.g., the welding of refrigerator condensers, crossed-wire welding, refrigerator racks, gratings, grills etc.