Electric Arc Welding – Definition, Working Principle, Types and Applications:

Definition – By definition, arc welding is that process in which the pieces of metal to be welded are brought to the proper welding temperature at point of contact by the heat liberated at the arc terminals and in the arc stream so that the metals are completely fused into each other, forming a single solid homogeneous mass, after it solidifies.

Working Principle:

In this electric arc welding process, an electric arc is produced by bringing two conductors (electrode and metal piece) connected to a suitable source of electric current, momentarily in contact and then separating by a small distance. The current continues to flow across the small gap and gives intense heat. The heat developed is utilised to melt the part of the workpiece, and the filler metal and thus forms the joint. So arc welded joint is a union of metal parts made by localised heating without any pressure. That is why sometimes this type of welding is known as the non-pressure welding. The heat developed by arc is also used for cutting of metal.

The voltage necessary to strike the arc is higher than that required to maintain it. The temperature is of the order of 3,600°C, at which mechanical pressure is not required for jointing. According to BSS 638 maximum voltage specified for welding is about 100 volts for the safety of the operator. The arc voltage varies from 20 to 40 volts and current from 50 A in sheet metalwork to 1,000 A in heavy automatic welding.

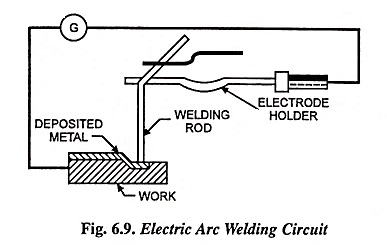

The welding circuit for an electric arc welding process is shown in Fig. 6.9. The welding circuit consists of a welding machine, two leads, an electrode holder, an electrode and the work itself.

Applications:

The electric arc welding is widely used for joining of metal parts, the repair of fractured castings and the fillings by the deposition of new metal on worn-out parts.

Types of Electric Arc Welding:

Arc welding is again subdivided into five groups namely

- carbon arc welding,

- metal arc welding,

- atomic hydrogen arc welding,

- inert gas metal arc welding and

- submerged arc welding.