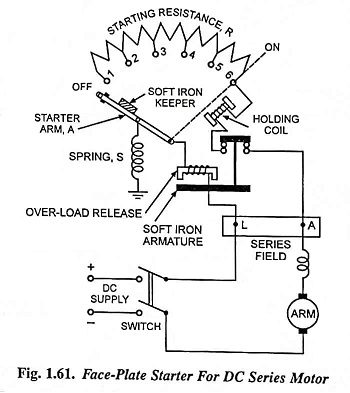

DC Series Motor Starter Working Principle:

The series motor starter serves the same purpose as the three- and four-point starters employed with shunt and compound wound motors. However, series motor starter has different internal and external connections.

A series motor starter with holding coil and overload release is illustrated in Fig. 1.61. Holding coil protects the motor against “no volt” and “no load” whereas overload release protects the motor against the flow of excessive current.

For switching off the dc series motor, the line switch should always be opened rather than throwing back the starting arm, as in case of dc shunt and compound motors. If it is done, then heavy sparking is caused at the stud 1, because here the field circuit is broken and the entire energy stored in the magnetic field is dissipated in the form of heavy spark.

However, there is one significant difference. In case of a dc series motor, the flux does not remain constant but varies with the current because the line current, field current and armature current are the same. Thus the back emf at any given speed varies as the current varies between the upper and lower limits. The practical result of this is that a series motor starter has a smaller number of steps than that required for a starter of a dc shunt motor of the same rating with the same current limits. This is because an increase in current causes increase in back emf and thus the current rise tends to be self-limiting. As a result of the fewer steps, the resistance of each section of the starter resistor is greater than for the shunt motor starter.

Since flux varies during the starting operation and its relation to the field current is non-linear, the determination of the number of steps is rather complicated.