High Pressure Mercury Vapour Lamp – Construction and Working:

The extensive use of the mercury vapour lamp depends entirely upon the versatility of the mercury vapour as regards pressure, temperature, voltage and other characteristics, each change resulting in a lamp of different spectral quality and efficiency.

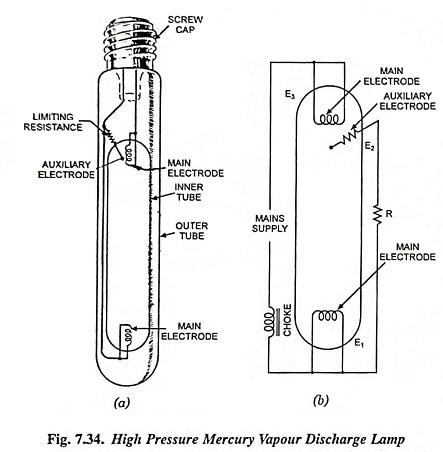

The mercury vapour discharge lamp is similar in construction to the sodium vapour discharge lamp. It consists of a discharge envelope enclosed in an outer bulb of ordinary glass. The discharge envelope may be of hard glass or quartz. The space between the bulb is partially or completely evacuated to prevent heat loss by convection from the inner bulb. The outer bulb absorbs harmful ultraviolet rays. The inner bulb contains argon and a certain quantity of mercury. In addition to two main electrodes a starting (auxiliary) electrode is connected through a high resistance (as shown in Fig. 7.34) is also provided. The main electrodes are made of tungsten wire in the shape of helix. In this case no separate heater is required for the cathode which is heated by the constant bombardment of the heavy mercury ions.

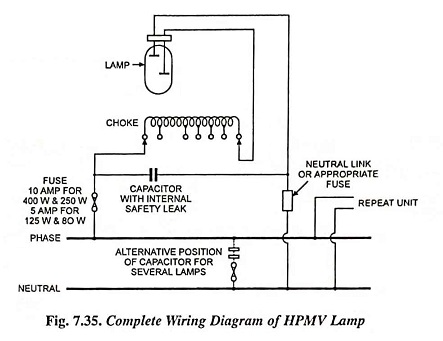

The lamp has to have auxiliary equipment for use with standard mains voltage, and the necessary connections are shown in Fig. 7.35. The choke is provided to limit the current to a safe value. This choke lowers the power factor, so a capacitor is connected across the circuit to improve the power factor. These lamps must be operated vertically, since if they are used horizontally convection will cause the discharge to touch the glass bulb, which will fail. Lamps which are intended to operate horizontally are fitted with a magnetic device which will hold the luminous column central.

Complete wiring diagram for high pressure mercury vapour discharge lamp is shown in Fig. 7.35.

When the supply is switched on, full mains voltage is applied between the auxiliary electrode and neighboring main electrode; this breaks down the gap and a discharge through the argon gas takes place. This enables the main discharge to commence. As the lamp warms up, mercury is vaporized, increasing the vapour pressure and the luminous column becomes brighter and narrower. The lamp requires 4 or 5 minutes to attain full brilliancy. If the supply is interrupted, the lamp must cool down and the vapour pressure be reduced before it will start. This takes 3 or 4 minutes. The temperature of operation inside the inner bulb is about 600°C. It gives greenish blue colour light, which causes colour distortion. The efficiency is about 30-40 lumens/watt. These lamps are manufactured in 250 and 400 watt ratings for use on 200-250 volts ac supply mains. The pressure of vapour in these lamps is 2-3 atmosphere. Lamps of this type are used for general industrial lighting, railway yards, ports, work area, shopping centres etc., where greenish blue colour light is not objectionable.

lamp described above is MA type. Another type, which is manufactured in 300 and 500 watt rating for use on ac as well as dc supply mains, is MAT type. This is similar to MA type except that choke is not used as a ballast. Space between two tubes instead of being evacuated consists of a tungsten filament in series with a discharge tube which acts as a ballast. When the supply is switched on, it operates as a filament lamp, its full output being given by the outer tube. At the same time the discharge or inner tube begins warming up and at a particular temperature a thermal switch operates cutting a part of the filament and thereby increasing the voltage across the discharge tube. The filament contributes a considerable portion of red rays. The combination of the rays from the filament and the blue radiations from the discharge tube produce a useful colour. As the filament acts as a resistance, the overall power factor of the lamp is about 0.95 and therefore, capacitor is not required.

Lower wattage lamps, such as 80 and 125 watts, are manufactured in a different design and using high vapour pressure of about 5-10 atmosphere. These are known as MB types. These operate in a manner similar to MA type except that resistance in series with starting electrode is large and outer bulb is of quartz, (not of ordinary glass) in order to withstand high temperature so that these lamps can be used in any position.

Advantages of High Pressure Mercury Vapour Lamp:

- It is very energy efficient.

- It provides light with high intensity

- It produces a clear white light

Disadvantages of High Pressure Mercury Vapour Lamp:

- It is very sensitive

- It takes around 8 minutes to warm up before it will glow fully.

- Maintenance is very poor.

Applications of High Pressure Mercury Vapour Lamp:

- It is used as security lights.

- It is used in industrial areas.

- It is also used as street lights.