Geothermal Power Plant Working Principle:

Geothermal Power Plant Working Principle – The growing demand of power will exhaust all fossil fuel sources in few decades. Therefore there is a permanent need for unconventional energy sources such as sun, wind, tidal and geothermal. The geothermal energy has a great potential and is being commercially exploited in few developed countries. 94% of the earth is molten. Only the outer shell is a solidified rocks which ranges in thickness from 6 to 150 km. The temperature at the centre of the earth (core) is around 3100°C and the temperature at the junction between the magma body and crust is around 1200°C. (i.e.,) the temperature at which most rocks melts. The crust of the earth is an excellent insulator, allows only little amount of heat to reach earth surface. When the heat escapes from the crust reaches water source it evaporate the water and converts it into steam. This steam is converted into useful work (or) power.

As we travel down earth’s surface radially, there exists a temperature gradient of 0.03 °C per metre. Thus a 30°C increase in temperature can be obtained per kilometer depth from the earth’s crust. There are many local hot spots just below the surface where the temperatures are much higher than expected. Ground water, when comes into contact with these hot spots, either dry or wet steam is formed. By drilling holes to these locations, hot water and steam can be tapped and these can be used for power generating or space heating.

Geothermal energy is the primary energy from earth’s own interior. The geothermal energy from earth’s interior is almost inexhaustible as solar, wind and tidal energy. Geothermal energy can be used for power generation.

Geothermal energy is present all over the entire extent of earth surface, except the volcanic areas.

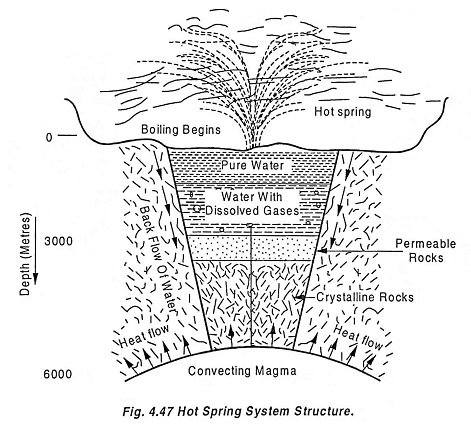

Fig. 4.47 shows how hot springs are produced through hot magma (molten mass), the fractured crystalline rocks, the permeable rocks and percolating ground water.

The three primary means of heat transfer from the earth interim are

- Direct heat conduction.

- Rapid injection of ballastic magma along natural rifits from deep earth’s mantle.

- Bubble like magmas that buoys upwards towards the surface.

Geothermal sources:

These are the five categories of Geothermal Power Plant Working Principle that have been identified

- Hydrothermal corrective system

- Dry steam fields

- Wet steam fields

- Hot water fields

- Geopressure resources

- Petro-thermal (or) hot dry rocks (HDR) thermal

- Magma resources

- Volcanoes

From the above mentioned geothermal sources the best resources for geothermal energy are Hydrothermal convective sources and dry rock is also being considered.

Hydrothermal convective system:

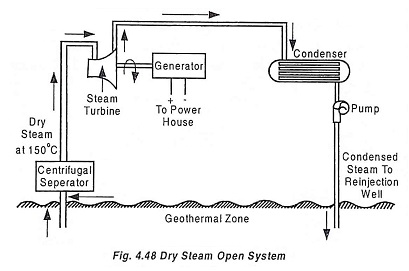

1. Dry steam systems

The arrangements of the components of dry steam system is shown in Fig.4.48. This system consists of pump, condenser, steam turbine and generator.

Working

The centrifugal separator separates the liquid particles and suspended solid particles from the steam coming out from geothermal zone and directs the steam into turbine. The turbine is directly coupled with generator.

Then the dry steam passes through condenser and the condensed water is pumped into the reinjection well. After depletion of thermal energy in geothermal region or insufficient supply of steam, to keep uninterrupted steam supply, new wells must be drilled.

2. Wet steam system

The main problem in this type of plant is salt corrosion. There is a need for steam separation and brine reinjection to avoid ground subsidence. This type of power plant requires larger area. This type of power plants can be made more economical by associating with chemical industries with power plant to make use of brine solutions and gaseous effluent.

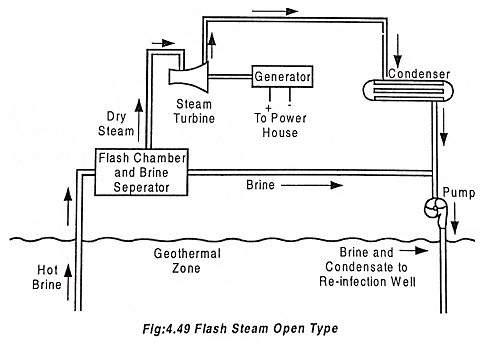

The arrangement of component of wet steam system or flash steam open type system is shown in Fig.4.49.

Water at high temperature coming out of geothermal zone is directed to flash chamber where the water is converted into steam and also separates the brine. Then the steam from the flash chamber is directed to steam turbine which is directly coupled to generator. The steam coming out of turbine is condensed by condenser. From condenser the condensed steam and brine from the flash chamber is pumped and sent to re-injection well as shown in Fig. 4.49.

The temperature of reservoir is in between 200° to 300°C and the volume of reservoir is many tens of cubic kilometer and the reservoir must have a low permeability to keep the heat and the water. The water should not contain excessive salt otherwise salt corrosion and effluence deposition become serious problems.

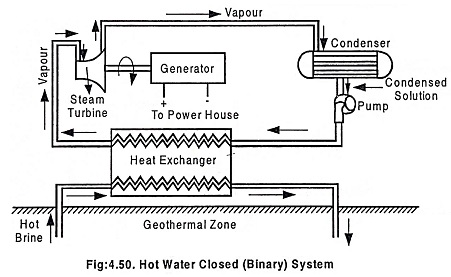

Binary system:

Many times, the temperature and pressure of water available is not sufficient to produce the flash steam. So in this type, the heat in the water is used as a closed system as shown in Fig. 4.50. In this system Isobutane (or) Freon is used as working fluid which is continuously recirculated. The main advantage with closed system is that, lower hot water temperature can be used and brine corrosion is prevented.

The working fluid Freon or Isobutane has a nature to absorb heat [which is used as a refrigerant in Refrigeration] & also rejects heats when condensed and converts into liquid solution. In this system the flash chamber is replaced by heat exchanger.

When the hot brine passes through the heat exchanger, it transfer the heat to working fluid. Then due to absorbtion of heat, working fluid is converted into vapour and allowed to pass through turbine where turbine is coupled with generator to produce power. This vapour then passes through condenser and condenses into liquid solution, which is pumped again to heat exchanger to absorb heat hence called as closed system.

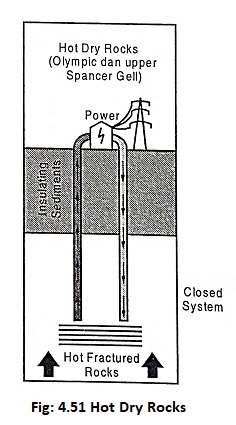

3. Hot dry rock system

In this type of geo thermal energy, heat content is found in the form of hot dry rock. In this type of energy, heat will have to be transferred to the surface by means of artificially injected water by means of specially contracted pathways and the rock will have to be fractured to give good contact of heat in between water and rock.

This type of Geothermal Power Plant Working Principle is more attractive, because one cubic mile of hot rock when it cooled from 350°C to 180°C, it will give energy of a major oil field, about (1/3) billion barrel of oils and it could yield about 8000 MW – year of energy.

4. Magmatic molten chamber systems

The temperature range of volcano is from 1000°C to 1300°C. More than 30% of energy from a volcano between 1150 °C and ambient temperature 25°C is recoverable above the solidification temperature of lava. Extraction of heat from magma is studied at a temperature of about 1450°C under laboratory conditions. Based on the experiment to produce 100 MW power, 400 m2 of heat exchange surface area is required, using an average value of 250 kW/m2 of heat extraction rate.

It is required to use a single 20 cm diameter tube extending upto 700 m into volcanic chamber. Extension of tube in magma chamber for magma source will be possible upto 4 to 5 kilometers of the surfaces.

The energy recovery from deeper source is very difficult because we need to drill for a large distance and solidification of magma around tubes reduces heat exchange rate. The above are some major problems in developing such system.

Advantages of Geothermal Power Plant:

- Geothermal energy is cheaper.

- It is versatile in its tape.

- It is the least polluting as compared to other conventional energy sources.

- It is amenable for multiple uses from a single resource.

- Geothermal power plants have the highest annual load factors of 85 percent to 90 percent compared to 45 percent to 50 percent for fossil fuel plants.

- It delivers greater amount of net energy from its system as compared to other alternative or conventional systems.

- Geothermal energy from the earth’s interior is almost as inexhaustible as solar or wind energy, so long as its sources are actively sought and economically tapped.

Disadvantages:

- Low overall power production efficiency (about 15% as compared to 35 to 40% for fossil fuel plants).

- Drilling operation is noisy.

- Large areas are needed for exploitation of geo-thermal energy.

- The withdrawal of large amounts of steam or water from a hydro-thermal reservoir may result in surface subsidence or settlement.