Working Principle of Combined Cycle Gas Turbine Power Plant:

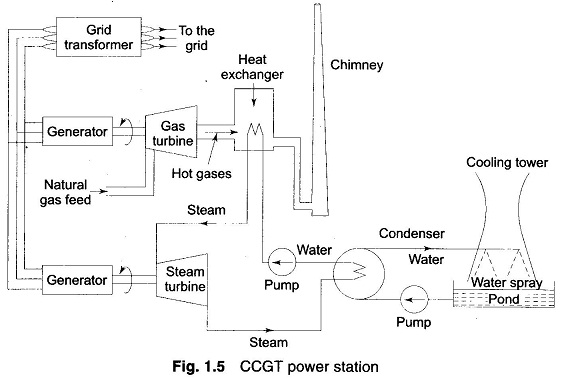

With increasing availability of natural gas (methane) (recent finds in Bangladesh) prime movers based on Gas Turbines have been developed on the lines similar to those used in aircraft. Gas combustion generates high temperatures and pressures, so that the efficiency of the gas turbine is comparable to that of steam turbine. Additional advantage is that exhaust gas from the turbine still has sufficient heat content, which is used to raise steam to run a conventional steam turbine coupled to a generator. This is called Combined Cycle Gas Turbine (CCGT) plant. The schematic diagram of CCGT is shown in Fig. 1.5.

The Working Principle of Combined Cycle Gas Turbine Power Plant has a fast start of 2-3 min for the gas turbine and about 20 minutes for the steam turbine. Local storage tanks of gas can be used in case of gas supply interruption. The unit can take up to 10% overload for short periods of time to take care of any emergency.

CCGT unit produces 55% of CO2 produced by a coal/oil-fired plant. Units are now available for a fully automated operation for 24h or to meet the peak demands.

In Delhi (India) a CCGT unit of 34114W is installed at Indraprastha Power Station.

There are currently many installations using gas turbines in the world with 100 MW generators. A 6 x 30 MW gas turbine station has already been put up in Delhi. A Gas Turbine Power Plant unit can also be used as synchronous compensator to help maintain flat voltage profile in the system.