Gas Cooled Reactor Working Process:

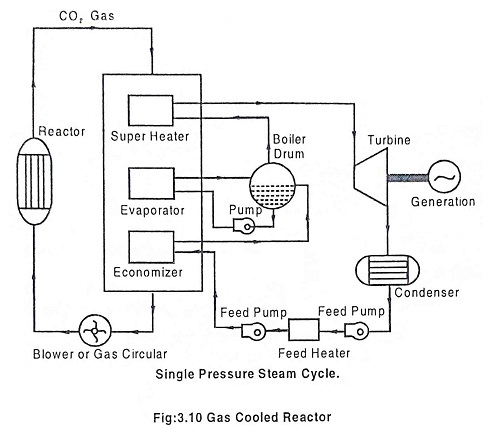

Gas Cooled Reactor Working Process – This type of reactor is cooled by the gas. The heat carried by the gas from the reactor is either used for generating steam in the secondary circuit like PWR (or) it can be directly used as the working fluid in the gas power plant. The indirect circuit type gas cooled reactor is shown in Fig. 3.10.

In this type, the carbon dioxide gas is used as primary coolant which in turn generates steam in the secondary circuit. Carbon dioxide gas is used to carry away the heat produced in the reactor. The gas is circulated at a pressure of about 7 bar.

The gas flowing up through each of the channels round the elements leaves the reactor at the top. This gas flows to heat exchanger and transfers its heat to water so that it gets converted into steam. The gas is recirculated with the help of gas blowers. The steam drives the turbines which in turn drives alternator to generate electricity.

Advantages:

- Fuel processing is simple.

- The use of CO2 as coolant completely eliminates the possibility of explosion in reactor.

- No corrosion problem.

Disadvantages:

- The loading of fuel is costly.

- Large vessel is required since power density is very low.

- The leakage of gas is a serious problem, in case helium is used instead of CO2.