Draught System in Power Plant – Definition and Classification

Draught is an essential part in thermal power plant. The functions of the draught system are:

- To supply required quantity of air to the furnace for combustion of fuel.

- To draw the combustion products through the system.

- To remove burnt products from the system.

Draught is defined as the small pressure difference required between the fuel bed (furnace) and out side air to maintain constant flow of air and to discharge the gases through chimney to the atmosphere. Draught can be obtained by using chimney fan, steam (or) air jet (or) combination of these.

Classification of Draught System:

1. Natural draught: In this, only chimney is used for producing the draught.

2. Artificial draught: In this, the draught is produced by steam jet or by fan.

- Steam jet draught: Steam jet is used for creating draught in the system.

- Mechanical draught: Fan or blower is used for creating draught in the system.

- Induced draught: The flue gas is sucked through the system by a fan or steam jet.

- Forced draught: The air is forced into the system by a blower or steam jet.

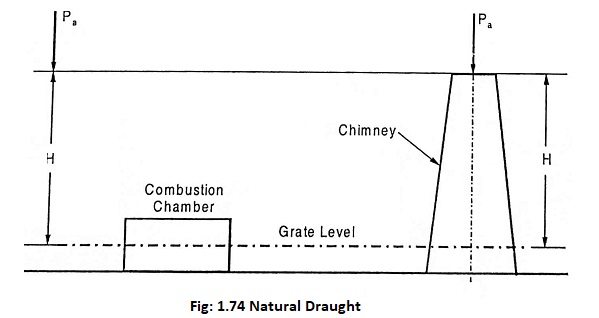

Natural draught:

In natural draught, a tall chimney is erected. The chimney is a vertical tubular masonry structure or reinforced concrete. It is constructed for enclosing a column of exhaust gases to produce draught. The flue gases are discharged at enough height so that the air pollution is prevented. The natural draught created by the tall chimney is due to the temperature difference between hot gases in the chimney and cold atmospheric air outside the chimney.

Let

- H – height of the chimney above the grate level in m

- Pa – atm. pressure in N/m2

- wa and wg – weight densities of atm air and hot gases

The pressure at grate from chimney side in N/m3

The pressure at grate from atmospheric side.

Since, the density varies along the height of the chimney, the average density is considered for calculation.

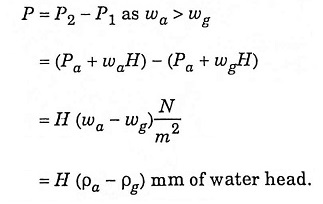

The net pressure acting on the grate is given by

The pressure difference in chimney should be between 10 to 12 mm of water head.

Merits of natural draught:

- No external power is required.

- Since the gases are discharged at high level, air pollution is less.

- Maintenance cost is practically low.

- It has longer life.

- Capital cost is less than the artificial draught.

Demerits of natural draught:

- Maximum pressure available for producing draught is less.

- Flue gases have to be discharged at high temperature for better draught resulting in wasting of heat.

- Heat cannot be extracted for economizer, superheater (or) air-pre heater since the effective draught would be reduced.

- Overall efficiency of the plant is reduced because the gases are discharged at high temperature.

- Poor combustion and increased specific fuel consumption.

- Not flexible under peak load.

Artificial draught:

In modern power plants, the draught should be flexible to meet the fluctuating loads and it should be independent of atmospheric conditions. Nowadays, the modern power plants produce 20,000 tons of steam per hour. To achieve this, the aid of draft fans become must and by employing the draft fans, the height of the chimney would be reduced. The artificial draught is more economical when the required draught is above 40 mm of water. The artificial draught is classified into forced draught, induced draught and balanced draught.

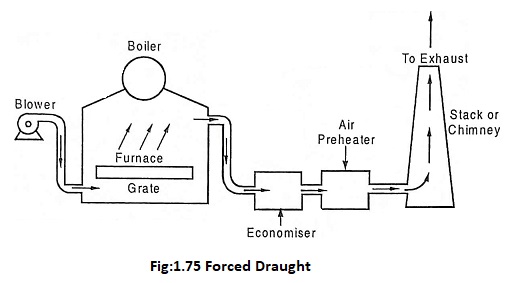

Forced draught:

In this draught system, the blower is located at the base of the boiler near the grate. The blower is driven by steam or electricity.

Air is forced to the furnace by forced fan and the flue gases are forced to chimney through economiser and air preheater. This system is known as positive draught system since the pressure of air and hot gases in this draught system are above atmospheric pressure. The chimney discharges the hot gases at higher level to prevent air pollution.

Merits:

- Since the fan handles cold air, the fan size and the power required is less.

- No need of water cooled bearings because the air being handled is cold air.

- Pressure throughout the system is above atmospheric pressure so the air leakage into the furnace is reduced.

Demerit:

- The furnace cannot be opened for firing and inspection because while opening, the high pressure air will try to blow out suddenly and furnace may stop.

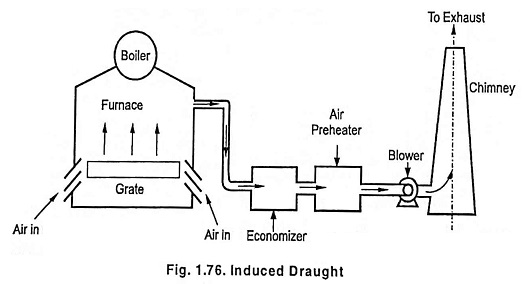

Induced draught:

In a induced draught, a blower is placed near (or) at the base of the chimney. The fan is driven by steam or electricity. The fan sucks the flue gas from the furnace creating a partial vacuum inside the furnace. Thus atmospheric air is induced to flow through the furnace to aid the combustion of fuel. The flue gases drawn by the fan passes through chimney to the atmosphere.

Merits:

- The gases could be discharged at lower temperature after recovering most of their heat in economizer and air pre heater.

- The chimney height can be reduced since it discharges flue gases only.

Demerits:

- The furnace can not be opened for firing and inspection because while the furnace is opened the cold air enters the furnace and dilute the combustion and hence the heat may be lost.

- Water cooled bearings are needed for the fan to with stand high temperature of the flue gases.

- Air leakage into the furnace is possible since the pressure inside the furnace is below atmospheric

Balanced draught system:

In this induced draught system, when the furnace is opened for firing, the cold air enters the furnace and dilute the combustion. In the forced draught system, when the furnace is opened for firing, the high pressure air will try to blow out suddenly and furnace may stop. Hence the furnace cannot be opened for firing or inspection in both the systems, if they are used separately.

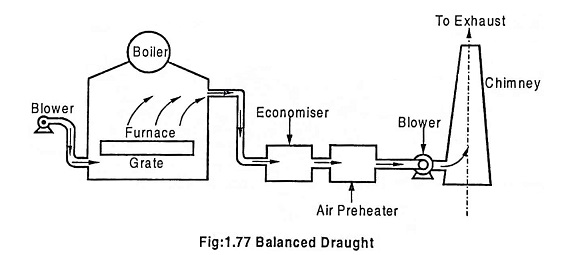

Balanced draught which is a combination of induced and forced draught is used to overcome the above stated difficulties.

In this, one blower is located at the base of the boiler and other is placed at the base of the chimney. The pressure distribution in the balanced draught is uniform. The pressure of air below the grate is above atmospheric pressure. This helps uniform combustion. The pressure of air above the grate is below atmospheric. This helps in removing hot flue gases quickly from the combustion zone. The pressure inside the furnace is nearly atmospheric. Hence, there is no blow out of flames or no entry of outside air into the furnace if the doors are opened for firing and inspection.