Feed Water Treatment in Power Plant and Types:

Raw water coming from different sources contains dissolved salts and un-dissolved or suspended impurities. Therefore it is necessary to remove harmful salts dissolved into the water before feeding it to the boiler. It is Feed Water Treatment.

Need for feed water treatment:

- Scaling on the inside wall of different heat-exchangers due the deposition of dissolved salts and suspended impurities will form and thus these will create excessive pressure and thermal stress inside the heat-exchangers, which may lead to the explosion and serious hazards for boilers.

- The dissolved salts may react with various parts of boiler through which it flows, thereby corrode the surfaces.

- Corrosion damage may occur to turbine blades.

Hence, feed water treatment is very much required to remove such dissolved and suspended impurities from water before feeding it to boiler.

Arrangements for Feed Water Treatment:

For continuous supply of feed water to boiler, after removing impurities, there are two types of plant generally incorporated. These are:

- Chlorination

- Demineralization plant (DM plant)

- Reverse Osmosis plant (RO plant)

1. Chlorination:

Chlorine (C12) has been used for many years to treat municipal and industrial water and waste waters to control microorganisms because of its capacity to inactivate most pathogenic microorganisms quickly. The effectiveness of chlorine is dependent on the chlorine concentration, time of exposure, and the pH of the water. Chlorine is used for treating potable water where a residual chlorine concentration near 0.5 mg/L is commonly used. In a water treatment scheme, fouling of water intake lines, heat exchangers, sand filters, etc., may be prevented by

maintaining a free residual chlorine concentration of 0.5 – 1.0 mg/L or higher, dependent on the organic content of the incoming water. Chlorination for RO treatment has been applied usually where biological fouling prevention is required (i.e., typically for surface waters). Chlorine is added continuously at the intake, and a reaction time of 20-30 min should be allowed. A free residual chlorine concentration of 0.5 – 1.0 mg/L is allowed. A free residual chlorine concentration of 0.5 – 1.0 mg/L should be maintained through the whole treatment line. Dechlorination upstream of the membranes is required, however, to protect the membranes from oxidation.

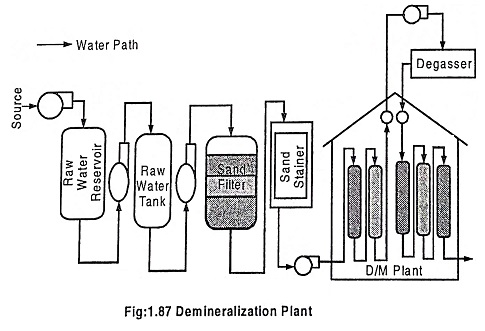

2. Demineralization Plant:

The function of demineralization plant is to remove dissolved salt by ion exchange method (chemical method) and there by producing pure feed water for boiler.

The salts which make the water hard are generally-chloride, carbonates, bi-carbonates, silicates & phosphates of sodium, potassium, iron, calcium and magnesium.

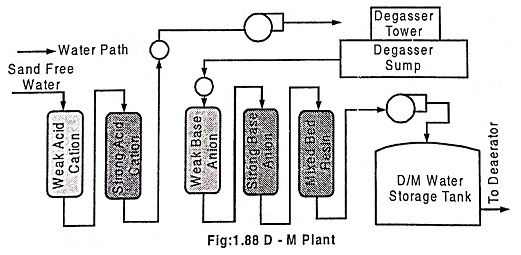

In DM plant, there are three types of resin used for boiler feed water treatment process —

- Cation exchange resin

- Anion exchange resin

- Mixed Bed resin

1. Cation Exchange Resin:

Thus H2SO4, H2CO3 are also produced.

We have removed Na+ but the water has become acidic.

2. Anion Exchange Resin:

This way we have eliminated CI– and thus acidity of the water is avoided.

Similar reaction for H2SO4 also.

3. Mixed Bed Resins:

These mixed bed resins are used in Demineralization plant of feed water treatment, to remove the ions (especially Na+ and SO2-3) which may further present in the water after forgoing process of purification.

Degasser

The function of degasser tower is to remove carbonate ions by forming cabon-di-oxide. In degasser tower, stream of water is poured from top & air is blown from bottom to top. In the pressure of air, the carbonic acid (H2CO3) present in the water dissociates into H2O and CO2.

This CO2 is free to mix with air.

3. Reverse Osmosis Plant (RO Plant):

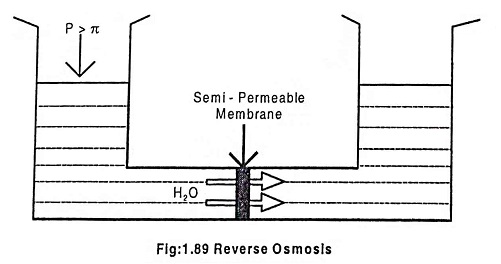

Like demineralization plant, there is another stage of water treatment which is known as reverse osmosis plant (RO plant). It uses the process known as reverse osmosis to produce salt-free water. The theoretical aspect is described below:-

Reverse Osmosis: On the higher density solution (lower density solvent) if a pressure (P), greater than osmotic pressure (π) is applied, then the solvent molecules pass through the semi-permeable membrane from higher density solution to lower density solution. This phenomenon is called reverse osmosis. This one is the important stage for boiler feed water treatment process.

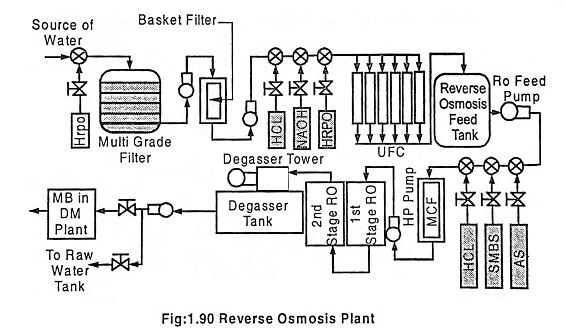

Reverse Osmosis Plant

In RO plant using reverse osmosis phenomenon salt-free water is taken out from raw water after the sand filtration. Purity of the salt-free water depends on effectiveness of the permeable membrane.

The layout of a typical Reverse Osmosis Plant is given below

Steam air pre-heater require some steam which will reduce the efficiency of the power plant.

The procedure is described below:

- Sodium hypochlorite (NaOCI) is injected to raw water to kill the algae or bacteria present in the raw water. Otherwise they may cause harm to the multi grade-filter (MGF).

- The multi-grade filter is the primitive type of filter where sand, stone-chips, stones are used in stacks to remove the large size suspended particles from the raw water.

- The net filter again removes medium-size suspended particles, where the raw water passes through the net minute vents.

- Then by ultra-filtration very small suspended particles are removed. After long usage of ultra-filtration unit, it requires back-wash, and then it is back washed with water & three chemicals, viz.. HCL, NaOH and NaOCI (Sodium Hypochlorite). HCI Removes iron by dissolving it. It also removes the basic salts those are rejected on UFU.

- NaOH ← It helps to remove acidic salt.

- NaOCI ← To kill algae and bacteria inside the UFU.

- After ultra-filtration the water is stored into RO feed tank & then pumped with RO feed pump of Reverse Osmosis Plant. In the channel the water is mixed with HCL (for pH controlling, as the water coming from RO plant or RO permeate water should have pH around 6.0) and SMBS (sodium meta bi-sulphate) [Na2S2O5]. Due to the presence of sodium hypochlorite, the water is chlorinated. To remove excess chlorine SMBS is used. If excess chlorine is not removed, then the semi-permeable membrane may get damaged. It is also mixed with anti-scaling reagent (AS), which reacts with those chemicals which form scale inside the channel.

- Then the water is passed through micro-cartridge filter (MCF) which removes the other suspended particles & the precipitate formed by the reaction of anti-scaling reagent with the scaling chemicals.

- In this stage of boiler feed water treatment, the water is fed to RO unit by HP pump, where after successive filtration by 1St & 2nd stage, RO it is fed to degasser unit.

- After degasification, the water is passed through DM plant – MB (Mixed bed) resin & stored into DM water storage tank.