Pumped Storage Power Plant – Operating Modes and Types:

Introduction – Pumped Storage Power Plant are generally used for peak loads.

An interconnected system of pumped storage plants are more suitable, when the quantity of water available for power generation is insufficient in peak period and also highly suitable for areas of high dam construction.

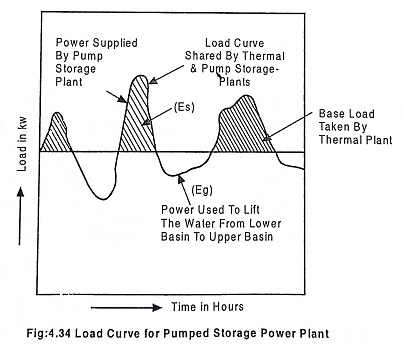

Pumped storage plant essentially consists of head water pond and a tail water pond. During off-peak period the water from the tail water pond is pumped with the help of pump using the energy available from the thermal power plant as shown in Fig.4.34.

The energy available during off-peak period is stored as a hydraulic potential energy by lifting the water from lower level to higher level. Thus the same energy is utilized during peak load period by supplying water from the upper basin to the hydraulic turbine through penstock. Hence the quantity of water pumped may be equal to the water passing through the turbine during peak load period depending upon the requirement.

Number of interconnected pumped storage hydroplants uses the concept of pump storage for meeting peak loads and to decrease the thermal station operating cost.

Operating modes of pumped storage plant:

| SL. NO. | Mode | Duration | Conversion |

| 1 | Peak load hours | Turbine-generator | Hydro-electrical |

| 2 | Off-peak hours | Motor-pump | Electrical-Hydro |

There are three types of operating cycles (i.e.,) Daily, weekly and yearly.

Types of pumped storage plant:

- Overground pumped storage plant

- Underground pumped storage plant

(i) Overground pumped storage plant

(a) Overground pumped storage system with hydro-electric power plant

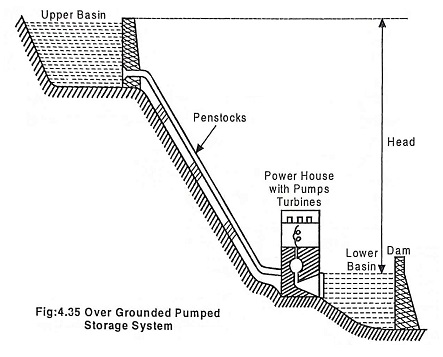

The Fig.4.35 shows the overground pumped storage system.

The system consists of

- Penstock

- Dam

- Powerhouse pumps & turbine

- Lower basin

- Upper basin

Upper basin is located at higher level and away from the power plant. The lower basin is located near power house where pumped storage plant is installed.

Working:

The water from upper basin is transmitted to lower basin by means of penstock through turbine and the water is stored in lower basin for pumping.

During low load condition, the water is pumped from lower basin to upper basin using the extra energy available. This water can be again used for generating power during peak load periods.

Pumping of water may be done seasonally (or) daily depending upon the nature of load on the plant and condition of site.

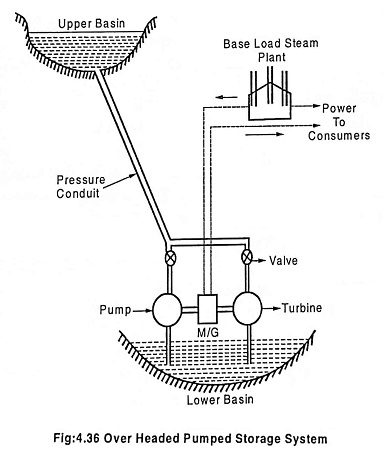

(b) Overhead pumped storage plant in combination with steam power plant

The over head pumped storage plant consists of

- Pressure conduit

- Upper basin

- Base load steam plant

- Turbine

- Motor (or) Generator

- Pump

The Fig.4.36 shows the over head pumped storage power plant in combination with steam power plant.

Working:

This type of plant is interconnected with steam plant. During low load conditions, the capacity of steam plant is used in pumping water. Then the pumped water is again used in peak load conditions.

The energy available from the quantity of water pumped by the plant is less than the energy input given during pumping operation. Again using the pumped water the power available is reduced due to losses occurring in prime mover.

(ii) Under ground pumped storage plant:

The concept of over ground hydel pumped storage is similar to under ground pumped storage plant except the upper basin is at ground level and the lower basin power plant is at underground.

This types of plants are preferred for sites having large under ground chamber or salt solution mines which can store water in lower reservoir. The underground pumped hydel plant does not depend upon the topology of low and high level reservoirs. The operating principle is similar to over ground pumped hydel systems.

Advantages

- There is an improvement in load factor of the power

- Load on the hydroelectric plant remains constant.

- The energy available during peak load periods is higher than the low load period including losses in pumping.

- The pumped storage plant can be constructed near to the load centers than the conventional hydel (or) thermal plant.

- The capacity of plant does not depend upon river flow and seasonal variations in flow.

Disadvantages

- It requires a minimum water head of 200 m.

- Dual energy conversion system is required for every pumped storage plant.