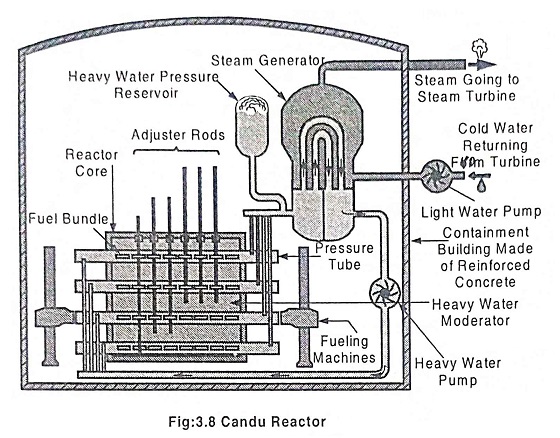

Canada Deuterium Uranium Reactor (CANDU):

It is a Canadian invented pressurized heavy water reactor which uses 99.8 percent of Deuterium oxide D2O (Heavy water) as moderator and coolant. The reactor uses 0.7% U235 (natural uranium) as its fuel. The Canada Deuterium Uranium Reactor consists of a steel cylinder with a horizontal axis containing number of pressure tube (channel) which are subjected to high internal pressure. The channels contains fuel elements and the pressurised coolant flows along the channels and fuel elements to remove the heat generated during the fission. The coolant flows in the opposite direction of its adjacent channel.

The fuel used in a Canada Deuterium Uranium Reactor is normal uranium oxide pellet (the uranium is unenriched or unbreeded). The pellets are packed in a corrosion resistance zirconium alloy tube, which is 0.5 cm long and its diameter is 1.3 cm called fuel rod. The short fuel rods are combined in bundles of 37 rods, there are 12 bundles placed end to end in each pressure tube. The reactor refuelling i.e. removal of spent fuel and replacement by fresh fuel is carried out while the reactor is operating.

A number of strong neutron absorber rods of cadmium are provided for control and protection of reactor, rods of cadmium are mainly used for reactor shut down and start up. In addition to this, there are other less strongly, absorber rod to control power variation during the operation and to produce uniform heat distribution though out the core.

The high temperature coolant leaving the reactor passes out through the outlet header to a steam generator where steam is generated at a temperature of about 265°C, the heated steam run the steam turbine, after work is done, the cold water from the turbine is pumped back into the reactor by the way of inlet header.

There are two coolant outlets and two inlet headers – one at each end of the reactor vessel corresponding to the opposite direction of coolant flow through the core. Each inlet and outlet header is connected to a separate steam generator and pump loop. The reactor vessel and steam generator system are enclosed by containment building made up of reinforced concrete.

Advantages of Canada Deuterium Uranium Reactor:

- Heavy water is used as moderator, which results in low fuel consumption.

- Enriched fuel is not required.

- The cost of vessel is less as it need not withstand a high pressure.

- Time needed to construct the reactor is less.

- Slowing the neutrons is easy as the moderator can be kept at low temperature.

Disadvantages:

- High standard of design, manufacture and maintenance is required.

- The cost of heavy water is high.

- Frequent leakage problems.

- Size of the reactor is extremely large.