Coal Burner Working Principle:

The coal burners are employed to fire the pulverised coal along with primary air into the furnace. The secondary air is admitted separately below the burner, around the burner or elsewhere in the furnace. The main requirement for a good coal burner is capability of producing uniform and stable flame with almost complete combustion of the fuel.

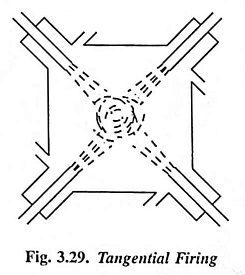

Coal burners can be classified according to their design and by their arrangement in the furnace. In one type of firing, say in opposed firing, the burners are placed on the opposite walls of the furnace and they fire directly against each other causing intimate mixing of the fuel and air. In second type of firing, say cross firing, the burners fire in the vertical direction and in horizontal direction and the fuel streams intersect with each other. And in third type of firing, called the tangential firing, the burners are placed in the corners of the furnace and they send horizontal streams of air and fuel tangent to an imaginary circle in the centre of the furnace (Fig. 3.29). Tangential firing results in intense turbulence and thorough mixing of the fuel and air. All the fuel and air nozzles can be titled 24° above and below the horizontal.

For firing crushed coal (not pulverised fuel) cyclon burners are employed. In such burners the crushed coal (max 6 mm size) from the feeder, and the primary air enter with a vortex motion at the centre of cyclon The secondary air is admitted separately in the vortex motion.

The fuel is quickly burnt and ash in the form of molten slag drains down the inner wall of the cyclon. Hot flue gases with 10-20% of the ash in the coal in the form of fly ash enter the furnace. Due to centrifugal action, most of this fly ash is thrown against the walls of the furnace and is drained away along with the molten film of slag.

The flue gases leaving the furnace are quite clean to flow through the rest of heat exchanger passages. Thus better heat transfer and good combustion is obtained. Also frequent cleaning requirement of furnace and fly ash trouble are very much reduced.