Construction of Induction Motor and Types of Rotor in Induction Motor:

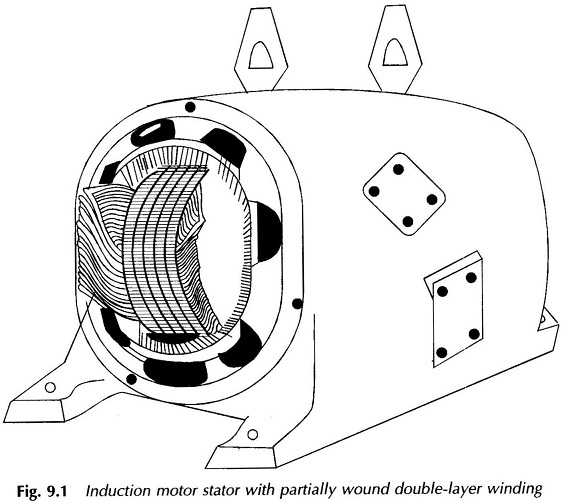

The stator of an Construction of Induction Motor is similar to that of a synchronous machine and is wound for three phases, modem practice being to use the two-layer winding. Figure 9.1 shows the stator of an induction motor.

Types of Rotor in Induction Motor:

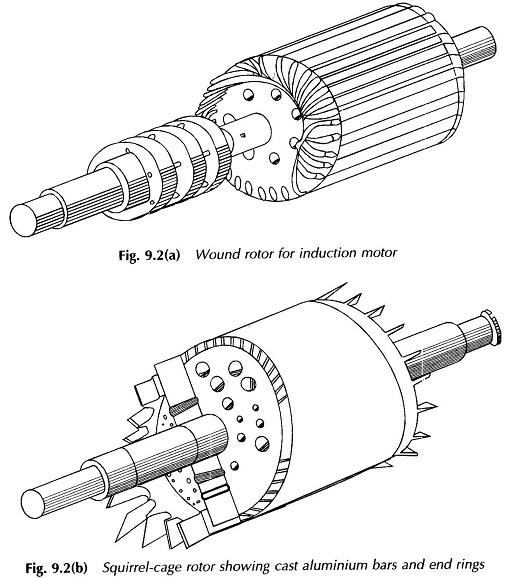

Two types of constructions are employed for the rotor wound rotor and squirrel cage rotor. The rotor core is of laminated construction with slots suitably punched in for accommodating the rotor winding rotor bars. The punched laminations are stacked and fitted directly onto a shaft in the case of small machines, while in the case of large machines a stack of annular punching’s of a suitable cross-sectional area are fitted onto a spider-web arrangement on the shaft.

Wound Rotor and Squirrel Cage Rotor Construction:

In Construction of Induction Motor the winding of a wound-rotor is polyphase with coils placed in the slots of the rotor core. It is similar to that of the stator except that the number of slots is smaller and fewer turns per phase of a heavier conductor are used. The rotor is wound and connected in star with three leads brought out of the machine via slip-rings placed on the shaft. The slip-rings are tapped by means of copper-carbon brushes. Wound-rotor construction is generally employed for large size machines to be used where the starting torque requirements are stringent. Figure 9.2(a) shows the view of a slip-ring rotor. External resistance can be included in the rotor circuit through slip-rings for reducing the starting current and simultaneously improving the starting torque.

The squirrel-cage rotor has solid bars of conducting material placed in rotor slots and shorted through end-rings on each side. Figure 9.2(b) shows the view of the squirrel-cage rotor of a small-size motor. In large machines alloyed copper bars are driven in the slots and are brazed onto copper end-rings. Rotors up to 50 cm diameter usually have diecast aluminium bars wherein the end-rings are also cast simultaneously with the same material by using a suitable mould. This is an economical process and is generally employed in mass production of small size induction motors.

The rotor circuit of a squirrel-cage machine cannot be tempered with and the machine has a low starting torque, while it has excellent running performance. Therefore, it cannot be used where a high starting torque is required. The starting torque of a squirrel-cage motor can be improved by employing either a double-cage rotor or a deep-bar rotor. Such type of construction serves the purpose of a medium starting torque requirement.

As already mentioned in Construction of Induction Motor, the rotor has a smaller number of slots than the stator and these must be a nonintegral multiple of stator slots so as to prevent magnetic locking of rotor and stator teeth at the time of starting. The slots in the induction machine are semi-enclosed so as to increase the permeance per pole so that the magnetization current, which is responsible for less than unity power factor of this motor, is kept within limits.

3 Phase Slip Ring Induction Motor:

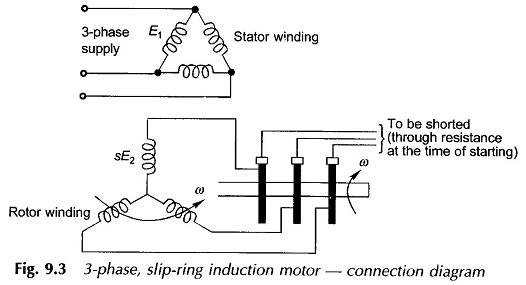

The connection diagram of a 3-phase slip-ring induction motor with delta-connected stator and star-connected rotor is drawn in Fig. 9.3. The rotor winding is connected to slip rings which are shorted through external resistances at the time of starting; the resistances are cut-out as the motor attains full speed.

The rotor of a squirrel-cage motor has permanently shorted bars, as stated earlier. These can be replaced from a circuit point of view by an equivalent wound rotor.