Repulsion Induction Motor – Construction, Working Principle and Applications:

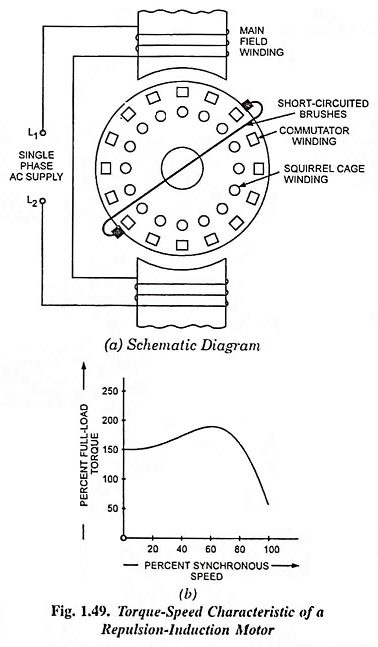

The repulsion induction motor has a single phase stator winding, as a repulsion-start induction motor has, but it has two separate and independent windings on rotor in common slots. The inner winding is a squirrel cage winding with rotor bars permanently short-circuited while outer winding is a repulsion or commutator winding similar to a dc armature winding.

When the motor starts, the squirrel cage winding, due to its high reactance, has no effect and the motor starts as a repulsion motor. As the motor speeds up, the current shifts from the outer winding to the inner winding owing to decreasing reactance of the inner winding with the increasing speed and the squirrel cage winding comes into action. At normal speed both of the windings develop torque, and the output of the motor is the combined output of both of the rotor windings.

The starting torque is about 2.5-3 times the full-load torque and its starting current is about 3-4 times the full-load current. The commutation of the motor is good at all speeds. No-load speed is above synchronous speed but normal speed is somewhat below synchronous one. No-load current is rather high, sometimes greater than the full-load current. The motor besides being costlier, has brushes always on the commutator involving sparking and maintenance problems. This motor is particularly suitable where the load can be removed entirely by the declutching or by loose pulley.

Applications:

Such a motor is used for applications requiring a high starting torque with essentially a constant running speed. The common ratings are 1/6 to 4 kW although in large ratings are also made. Common applications are household refrigerators, garage air pumps, gasoline pumps, compressors etc.