What is Electroforming Process? – Definition and Applications

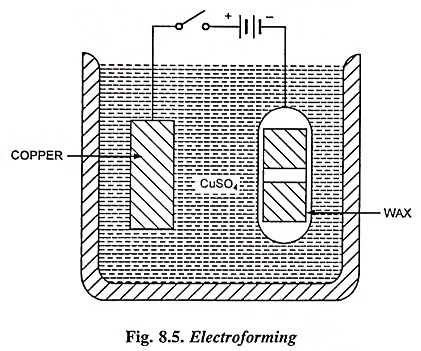

Reproduction of objects by electrodeposition on some sort of a mould or form is known as electroforming. This is another application of electrodeposition.

In the reproduction of coins, medals, engravings and the like, a mould is first made by impressing the object, say, in wax. The surface of the wax, which bears exact impressions of the object, is coated by powdered graphite in order to make it conducting. The mould is then dipped in an electroforming cell as a cathode. After obtaining coating of desired thickness, the article is removed and the wax core is melted out of the metal shell.

Applications

This process is employed in the manufacture of gramophone records, in which the original recording is done on a record made of wax composition. This mould is then coated with powdered gold to make it conducting and dipped into a blue vitriol electrolyte as the cathode. The solution is kept saturated by using a copper anode. The plating of copper on to the wax record produces a negative master plate which is used to stamp a large number of shellac discs.

Production of seamless tubes is another application of electroforming. Ferric chloride solution is used as an electrolyte, cast iron as anodes and revolving mandrel as cathode for producing iron tubes. For producing copper tubes copper sulphate acid solution is used as an electrolyte and cast copper is made as anode. A thin coating of material, which renders easy withdrawal of tube of material deposited, is given to the mandrel.