What is Cathode or Emitter and Types of Cathode?

The substance employed for electron emission is called a cathode or emitter. It is an essential part of an electron tube. The usefulness of a particular material as an emitter depends on (i) emission efficiency (ii) mechanical strength (iii) longevity at normal operating temperatures and (iv) stability of its surface under normal working conditions.

The substance selected as cathode or emitter should have low work function and high melting point. A substance having low work function but having melting point lower than that required for an appreciable emission density cannot be useful as an emitter.

Types of Cathodes:

- Directly heated cathodes and

- Indirectly heated cathodes.

When the cathode is made in the form of a filament, similar to a lamp filament, of a high resistance material and heated directly by passing a current through it. is known as a directly heated cathode or filamentary cathode. The cathode enclosing an electric heater, from which it is electrically insulated by a material of good thermal conductivity, is known as indirectly heated cathode. In either case the cathode is heated from a separate circuit and not by electron emission.

Directly heated cathodes or emitters have the following advantages over indirectly heated cathodes or emitters.

Cathodes itself is being used as a filament that is why power required to heat the cathode is less. The cathode temperature is attained quickly because it is directly heated. Directly heated cathode, being more efficient in converting heating power into thermionic emission, is generally employed in power tubes that require large amounts of emission and in small tubes operated from batteries where efficiency and quick heating are important.

On the other hand, directly heated cathodes or filamentary cathodes have the following drawbacks.

- After heating, directly heated cathode becomes mechanically weak and, therefore, it needs support to prevent it from getting in contact with other electrodes.

- The voltage drop across the filament is often comparable to the inter-electrode voltages.

- Because of direct heating the filament may expand and may touch a nearby existing electrode.

- Any variation in heating voltage affects the electron emission and thus introduces hum in the plate circuit.

In general cathodes are further classified as

- tungsten cathode

- thoriated tungsten cathode and

- oxide coated cathode.

Tungsten Cathode: Tungsten cathodes are made from pure tungsten metal as it is well suited as a source of emitting electrons. Tungsten is exceedingly refractory and has a high melting point (3,655 K). The tungsten filament operates at 2,400-2,500 K i.e. at a dazzling white heat and gives an emission of 0.1-0.3 A/cm2 of cathodes surface and 1-5 mA emission per watt of heating power. It has high work function (4.52 eV). It is very strong mechanically and resistant to gas poisoning and bombardment of gas particles. Owing to its low emission efficiency as compared to those of other types of emitters it is not used in receiving tubes i.e. small size electron tubes handling small powers. It is used mainly in high power tubes for radio-transmitters operating at high anode voltages where the conditions are too severe for other types of cathodes.

At the operating temperature tungsten evaporates slowly and life of tungsten cathode is therefore long. The life of tungsten cathodes depends upon the rate of evaporation. To have a longer life of tungsten cathodes and also having the more emission it is necessary that the cathode is operated at the correct temperature, because a small increase in temperature shortens the life while a reduction in temperature reduces the emission. As a rough rule it is said that increase of 5% in the filament voltage doubles the emission but halves the life.

Thoriated Tungsten Cathode: The main shortcoming with the pure tungsten cathode is that its work function is high e. it requires a large amount of power to emit a certain amount of electrons. This shortcoming is overcome in the thoriated tungsten filament which contains 98% tungsten and 2% thoria (thorium oxide) with a little amount of carbon. Carbon helps thorium to stick on tungsten. As the thorium is consumed in emission more thorium comes from the inner portion of the tungsten to maintain thorium layer.

Thoriated tungsten cathode emits cupious (plentiful) electrons at much lower temperature (about 1,900 °C) than a plain tungsten cathode, so requires less heating lower.

Thoriated cathodes usually operate at 1,800-1,900 K i.e. at a yellow heat giving about 1 A/cm2 emission of cathode surface and 20-40 mA per watt emission of heating power. These cathodes are usually used in tubes of moderate power operating at moderate anode voltages where conditions are too severe for oxide coated cathode but not severe as to require pure tungsten cathodes. It is not used in gas filled tubes as the thorium layer is damaged by the bombardment of positive charges.

Oxide Coated Cathode: An oxide coated cathodes consists of a wire or a ribbon of nickel or nickel alloy coated with oxides of alkaline-earth metals of barium and strontium (50 per cent each). The coating is about one two-hundredth of a cm thick and is now usually applied by spraying process. The materials actually used for coating are the carbonates and not the oxides since the oxides are chemically unstable in air. Such cathodes are employed for all small receiving valves and for small and medium valves not operating at too high anode voltages (not exceeding 1,000 V). Oxide coated cathodes provide highly efficient long life operation in the applications mentioned above.

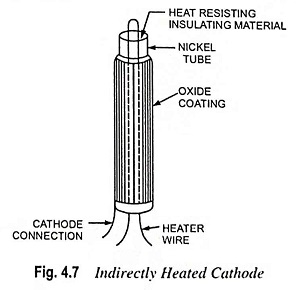

Indirectly Heated Cathode: An indirectly heated cathodes consists of a nickel tube coated with the electron emitting oxide layer on its surface and heated by a heater wire carrying a current. The heater wire is insulated from the nickel tube by a heat resisting material such as alumina (aluminium oxide) or magnesia (magnesium oxide).

The heater wire is usually worked at about 1,000 °C and maintains the nickel tube at about 800 °C which is sufficient for cupious emission from the oxide coating of the filament tube. As the cathode is not heated directly so the heating power can be drawn from ac or dc supply mains either directly or in case of ac mains through a transformer.

Indirectly heated cathode has many advantages. Cathode, being completely separated from the heating circuit, can be readily connected to any desired potential as required (independent of potential of heating circuit). Furthermore, because of relatively large mass of cylindrical cathode, it takes time to heat or cool and as such does not introduce hum due to heater voltage fluctuations. Finally ac can be used in the heater circuit to simplify the power requirements. Such cathodes (i.e. indirectly heated cathodes) are used in almost all modern receiving tubes designed for ac operation.