Turbine Flow Meter Working Principle:

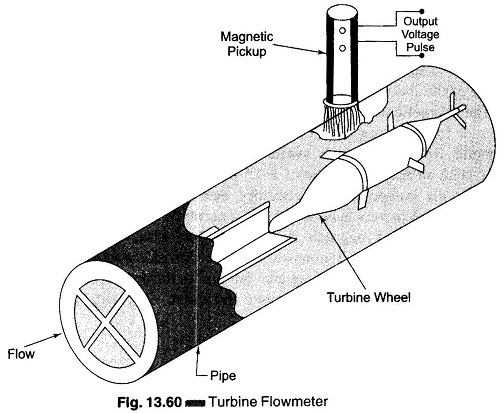

Turbine Flow Meter Working Principle – The Turbine Flow Meter is used for the measurement of liquid gas and gases of very low flow rate. It works on the principle of turbine. It consists of a multibladed rotor (called turbine wheel) which is mounted 90° to the axis of the flowing liquid as shown in Fig. 13.60.

The rotor is supported by the ball or sleeve bearings on a shaft which is retained in the flow meter housing by a shaft support section. The rotor is free to rotate about its axis.

The flowing liquid strikes the turbine blades (rotor) imparting a force to the blade surface which causes the rotation of the rotor. At a steady rotational speed, the speed of the rotor is proportional to the fluid velocity and hence to the volumetric flow rate. The speed of rotation is monitored by a magnetic pick up which is fitted to the outside of the meter housing.

The magnetic pick-up coil consists of a permanent magnet with coil windings which is mounted in close proximity to the rotor but internal to the fluid channel. As each rotor blade passes the magnetic pick-up coil, it generates a voltage pulse which is a measure of the flow rate. The total number of pulses gives a measure of the total flow.

The electrical voltage pulses produced can be totaled, differenced or manipulated by digital techniques, so that a zero error characteristic, using this technique, is provided from the pulse generator to the final read.

The number of pulses generated per gallon of flow, called the K factor is given by

where

- K = pulses per volume unit

- Tk = time constant in minutes

- f = frequency in Hz

- Q = volumetric flow rate is gpm (gallon per minute)

Turbine Flow Meter working principle provide very accurate flow measurement over a wide flow range. The accuracy range is ± 0.25 to ± 0.5% with excellent repeatability, i.e. precision ranging from ± 0.25% to as good as ± 0.02%.

The range of turbine meters is generally between 10 : 1 and 20 : 1; however, in a low flow rate it is less than 10 : 1.

Military turbine meters have a range greater than 100: 1.

Turbine meters are available in different sizes, ranging from 6.35 – 650 mm and liquid flow ranges from 0.1 – 50 000 gallons per minute.

These Turbine Flow Meter working principle are mostly used for military applications. They are also used in blending systems in the petroleum industry. They are effective in aerospace and airborne applications for energy fuel and cryogenic (liquid oxygen and nitrogen) flow measurements.

Advantages of Turbine Flow meter:

- Good accuracy

- Excellent repeatability and range

- Fairly low pressure drop

- Easy to install and maintain

- Good temperature and pressure ratings

- Can be compensated for viscosity variations

Disadvantages of Turbine Flow meter:

- High cost (expensive)

- Limited use for slurry applications

- Problems caused by non-lubricating fluids