Steam Turbine Efficiency:

The overall Steam Turbine Efficiency is quite low (about 29%) due mainly to two reasons. Firstly, a huge amount of heat is lost in the condenser and secondly heat losses occur at various stages of the plant. The heat lost in the condenser, cannot be avoided. It is because heat energy cannot be converted into mechanical energy without temperature difference. The greater the temperature difference, the greater is the heat energy converted into mechanical energy. This necessitates to keep the steam in the condenser at the lowest temperature. But we know that greater the temperature difference, greater is the amount of heat lost. This explains for the low efficiency of such plants.

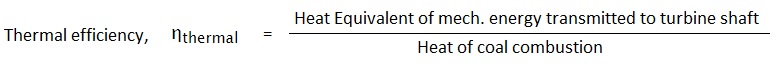

1. Thermal Efficiency:

The ratio of heat equivalent of mechanical energy transmitted to the turbine shaft to the heat of combustion of coal is known as thermal efficiency of steam power station.

The thermal efficiency of a modern steam power station is about 30%. It means that if 100 calories of heat is supplied by coal combustion, then mechanical energy equivalent of 30 calories will be available at the turbine shaft and rest is lost. It may be important to note that more than 50% of total heat of combustion is lost in the condenser. The other heat losses occur in flue gases, radiation, ash etc.

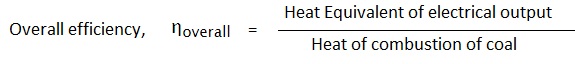

2. Overall efficiency:

The ratio of heat equivalent of electrical output to the heat of combustion of coal is known as overall efficiency of steam power station i.e.

The overall efficiency of a steam power station is about 29%. It may be seen that overall efficiency is less than the thermal efficiency. This is expected since some losses (about 1%) occur in the alternator The following relation exists among the various efficiency.

Overall efficiency = Thermal efficiency x Electrical efficiency

Equipments of Steam Power Station:

A modern steam power station is highly complex and has numerous equipment and auxiliaries. However, the most important constituents of a steam power station are :

- Steam generating equipment

- Condenser

- Mime mover

- Water treatment plant

- Electrical equipment.

1. Steam Generating Equipment:

This is an important part of steam power station. It is concerned with the generation of superheated steam and includes such items as boiler, boiler furnace, superheater, economiser, air pre-heater and other heat reclaiming devices.

(i) Boiler: A boiler is closed vessel in which water is converted into Steam Turbine Efficiency by utilising the heat of coal combustion. Steam boilers are broadly classified into the following two types :

(a) Water tube boilers, (b) Fire tube boilers

In a water tube boiler, water flows through the tubes and the hot gases of combustion flow over these tubes. On the other hand, in a fire tube boiler, the hot products of combustion pass through the tubes surrounded by water. Water tube boilers have a number of advantages over fire tube boilers viz., require less space, smaller size of tubes and drum, high working pressure due to small drum, less liable to explosion etc. Therefore, the use of water tube boilers has become universal in large capacity Steam Turbine Efficiency power stations.

(ii) Boiler furnace: A boiler furnace is a chamber in which fuel is burnt to liberate the heat energy. In addition, it provides support and enclosure for the combustion equipment i.e., burners. The boiler furnace walls are made of refractory materials such as fire clay, silica, kaolin etc. These materials have the property to resist change of shape, weight or physical properties at high temperatures. There are following three types of construction of furnace walls :

- Plain refractory walls

- Hollow refractory walls with an arrangement for air cooling

- Water walls.

The plain refractory walls are suitable for small plants where the furnace temperature may not be high. However, in large plants, the furnace temperature is quite high and consequently, the refractory material may get damaged. In such cases, refractory walls are made hollow and air is circulated through hollow space to keep the temperature of the furnace walls low. The recent development is to use water walls. These consist of plain tubes arranged side by side and on the inner face of the refractory walls. The tubes are connected to the upper and lower headers of the boiler The boiler water is made to circulate through these tubes. The water walls absorb the radiant heat in the furnace which would otherwise heat up the furnace walls.

(iii) Superheater: A superheater is a device which superheats the steam i.e., it raises the temperature of Steam Turbine Efficiency above boiling point of water This increases the overall efficiency of the plant. A superheater consists of a group of tubes made of special alloy steels such as chromium-molybdenum. These tubes are heated by the heat of flue gases during their journey from the furnace to the chimney.

The steam produced in the boiler is led through the superheater where it is superheated by the heat of flue gases. Superheaters are mainly classified into two types according to the system of heat transfer from flue gases to steam viz.

(a) Radiant superheater, (b) Convection superheater

The radiant superheater is placed in the furnace between the water walls and receives heat from the burning fuel through radiation process. It has two main disadvantages. Firstly, due to high furnace temperature, it may get overheated and, therefore, requires a careful design. Secondly, the temperature of superheater falls with increase in steam output. Due to these limitations, radiant superheater is not finding favour these days. On the other hand, a convection superheater is placed in the boiler tube bank and receives heat from flue gases entirely through the convection process. It has the advantage that temperature of superheater increases with the increase in steam output. For this reason, this type of superheater is commonly used these days.

(iv) Economiser: It is a device which heats the feed water on its way to boiler by deriving heat from the flue gases. This results in raising boiler efficiency, saving in fuel and reduced stresses in the boiler due to higher temperature of feed water. An economiser consists of a large number of closely spaced parallel steel tubes connected by headers of drums. The feed water flows through these tubes and the flue gases flow outside. A part of the heat of flue gases is transferred to feed water, thus raising the temperature of the latter.

(v) Air Pre-heater: Superheaters and economisers generally cannot fully extract the heat from flue gases. Therefore, pre-heaters are employed which recover some of the heat in the escaping The function of an air pre-heater is to extract heat from the flue gases and give it to the air being supplied to furnace for coal combustion. This raises the furnace temperature and increases the thermal efficiency of the plant. Depending upon the method of transfer of heat from flue gases to air, air pre-heaters are divided into the following two classes :

(a) Recuperative type, (b) Regenerative type

The recuperative type air-heater consists of a group of steel tubes. The flue gases are passed through the tubes while the air flows externally to the tubes. Thus heat of flue gases is transferred to air. The regenerative type air pre-heater consists of slowly moving drum made of corrugated metal plates. The flue gases flow continuously on one side of the drum and air on the other side. This action permits the transference of heat of flue gases to the air being supplied to the furnace for coal combustion.

2. Condensers:

A condenser is a device which condenses the steam at the exhaust of turbine. It serves two important functions. Firstly, it creates a very low pressure at the exhaust of turbine, thus permitting expansion of the steam in the prime mover to a very low pressure. This helps in converting heat energy of Steam Turbine Efficiency into mechanical energy in the prime mover. Secondly, the condensed steam can be used as feed water to the boiler. There are two types of condensers, namely :

(i) Jet condenser, (ii) Surface condenser

In a jet condenser, cooling water and exhausted steam are mixed together. Therefore, the temperature of cooling water and condensate is the same when leaving the condenser. Advantages of this type of condenser are : low initial cost, less floor area required, less cooling water required and low maintenance charges. However, its disadvantages are : condensate is wasted and high power is required for pumping water.

In a surface condenser, there is no direct contact between cooling water and exhausted steam. It consists of a bank of horizontal tubes enclosed in a cast iron shell. The cooling water flows through the tubes and exhausted steam over the surface of the tubes. The steam gives up its heat to water and is itself condensed. Advantages of this type of condenser are : condensate can be used as feed water, less pumping power required and creation of better vacuum at the turbine exhaust. However, disadvantages of this type of condenser are : high initial cost, requires large floor area and high maintenance charges.

3. Prime Movers:

The prime mover converts steam energy into mechanical energy. There are two types of steam prime movers , steam engines and Steam Turbine Efficiency. A Steam Turbine Efficiency has several advantages over a steam engine as a prime mover viz., high efficiency, simple construction, higher speed, less floor area requirement and low maintenance cost. Therefore, all modem steam power stations employ steam turbines as prime movers.

Steam turbines are generally classified into two types according to the action of steam on moving blades viz.

(i) Impulse turbines, (ii) Reactions turbines

In an impulse turbine, the steam expands completely in the stationary nozzles (or fixed blades), the pressure over the moving blades remaining constant. In doing so, the steam attains a high velocity and impinges against the moving blades. This results in the impulsive force on the moving blades which sets the rotor rotating. In a reaction turbine, the steam is partially expanded in the stationary nozzles, the remaining expansion takes place during its flow over the moving blades. The result is that the momentum of the steam causes a reaction force on the moving blades which sets the rotor in motion.

4. Water Treatment Plant:

Boilers require clean and soft water for longer life and better efficiency. However, the source of boiler feed water is generally a river or lake which may contain suspended and dissolved impurities, dissolved gases etc. Therefore, it is very important that water is first purified and softened by chemical treatment and then delivered to the boiler.

The water from the source of supply is stored in storage tanks. The suspended impurities are removed through sedimentation, coagulation and filtration. Dissolved gases are removed by aeration and degasification. The water is then ‘softened’ by removing temporary and permanent hardness through different chemical processes. The pure and soft water thus available is fed to the boiler for steam generation.

5. Electrical equipment:

A modern power station contains numerous electrical equipment. However, the most important items are :

(i) Alternators: Each alternator is coupled to a Steam Turbine Efficiency and converts mechanical energy of the turbine into electrical energy. The alternator may be hydrogen or air cooled. The necessary excitation is provided by means of main and pilot exciters directly coupled to the alternator shaft

(ii)Transformers: A generating station has different types of transformers, viz.,

(a) main step-up transformers which step-up the generation voltage for transmission of power.

(b) station transformers which are used for general service (e.g., lighting) in the power station.

(c) auxiliary transformers which supply to individual unit-auxiliaries.

(iii) Switchgear: It houses such equipment which locates the fault on the system and isolate the faulty part from the healthy section. It contains circuit breakers, relays, switches and other control devices.