What is Liquid Crystal Display (LCD)?:

Liquid Crystal Display (LCD) are passive displays characterized by very low power consumption and good contrast ratio. They have the following characteristics in common.

- They are light scattering.

- They can operate in a reflective or transmissive configuration.

- They do not actively generate light and depend for their operation on ambient or back lighting.

A transmissive Liquid Crystal Display has a better visual characteristic than a Reflective LCD. The power required by an LCD to scatter or absorb light is extremely small, of the order of a few μW/cm. Liquid Crystal Display operate at low voltages, ranging from 1-15 V.

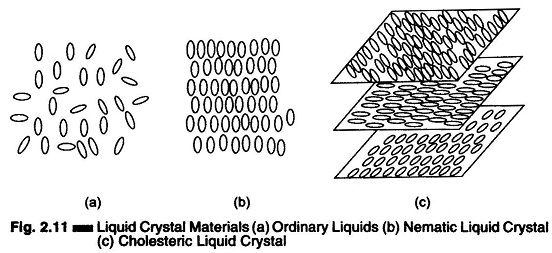

The operation of liquid crystals is based on the utilization of a class of organic materials which remain a regular crystal-like structure even when they have melted. Two liquid crystal materials which are important in display technology are nematic and cholesteric, as shown in Fig. 2.11.

The most popular liquid crystal structure is the nematic liquid crystal (NLC). The liquid is normally transparent, but if it is subjected to a strong electric field, ions move through it and disrupt the well ordered crystal structure, causing the liquid to polarise and hence turn opaque. The removal of the applied field allows the crystals structure to reform and the material regains its transparency.

Basically, the Liquid Crystal Display comprises of a thin layer of NLC fluid, about 10μ thick, sandwiched between two glass plates having electrodes, at least one of which is transparent. (If both are transparent, the LCD is of the transmissive type, whereas a reflective LCD has only one electrode transparent.)

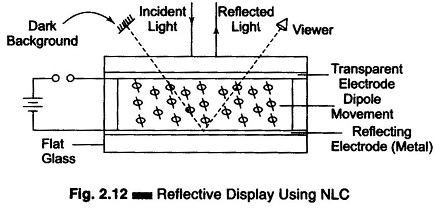

The structure of a typical reflective LCD is shown in Fig. 2.12.

The NLC material in Fig. 2.12 has a homogeneous alignment of molecules. While the glass substrate supports the LCD and provides the required transparency, the electrode facilitates electrical connections for the display. The insulating spacers are the hermetic seal.

The LCD material is held in the centre cell of a glass sandwich, the inner surface of which is coated with a very thin conducting layer of tin-oxide, which can be either transparent or reflective. The oxide coating on the front sheet of the indicator is etched to produce a single or multi segment pattern of characters and each segment of character is properly insulated from each other.

LCDs can be read easily in any situation, even when the ambient light is strong. If the read electrode is made transparent instead of reflective, back illumination is possible by a standard indicator lamp. Extending back illumination a step further by adding a lens arrangement. LCDs can be used as the slide in a projection system, to obtain an enlarged image.

Important Features of LCDs:

- The electric field required to activate LCDs is typically of the order of 104 V/cm. This is equivalent to an LCD terminal voltage of 10 V when the NLC layer is 10μ thick.

- NLC materials possess high resistivity > 1010Ω. Therefore the current required for scattering light in an NLC is very marginal (typically 0.1 μA/cm2).

- Since the light source for a reflective LCD is the ambient light itself, the only power required is that needed to cause turbulence in the cell, which is very small, typically 1 μW/cm.

- LCDs are very slow devices. They have a turn-on time of a few milliseconds, and a turn-off time of tens of milliseconds.

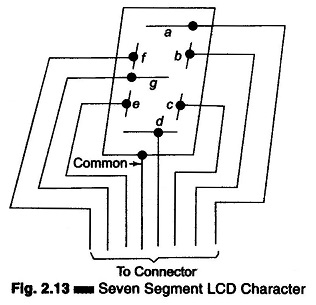

To sum up, LCDs are characterized by low power dissipation, low cost, large area and low operating speed. LCDs are usually of the seven segment type for numeric use and have one common back electrode and seven transparent front electrodes characters, as shown in Fig. 2.13. The back electrode may be reflective or transmissive, depending on the mode of operation of the display device.

Generally arrays of such characters are simultaneously fabricated using thin-film or hybrid IC technology for segments and conductors on glass plates, and then filled in with NLC material, followed by hermetic sealing. LCD arrays utilizing a dot-matrix are also possible, but they are not popular because of their slow operation.