Micro Hydel Power Plant – Components and its Workings:

Micro Hydel Power Plant was the most common way of electricity generating in the early 20th century. The first commercial use of hydroelectric power to produce electricity was a waterwheel on the Fox River in Wisconsin in 1882 that supplied power for lighting to two paper mills and a house. India has a century old history of hydropower and the beginning was from small hydro. The first hydro power plant was of 130 kW set up in Darjeeling during 1897, marked the development of hydropower in the country.

Micro hydro is a type of small scale hydroelectric power plant that makes advantage of naturally-flowing streams to produce 5 kW – 100 kW of electricity. This process produces no direct emission. Micro hydro can bring electricity to remote communities, ranging from a single home, to few hundred kilometer for selling into national grid. Water can be harnessed from small scale to large scale.

Small hydro is the largest contributor of electricity from renewable energy sources, over the last few decades. Development of small hydro power projects are done mainly due to its benefits particularly concerning environment and ability to produce power in remote areas. Small hydro projects are economically viable and have relatively short gestation period. A general classification of hydro power plant is as follows.

Micro hydel development:

| Type | Capacity |

| Large-hydro | More than 100 MW and usually feeding into a large electricity grid |

| Medium-hydro | 15 – 100 MW – usually feeding a grid |

| Small-hydro | 1 – 15 MW – usually feeding into a grid |

| Mini-hydro | Above 100 kW, but below 1 MW; either stand alone schemes or more often feeding into the grid |

| Micro-hydro | From 5 kW up to 100 kW; usually provided power for a small community or rural industry in remote areas away from the grid |

| Pico-hydro | From a few hundred watts up to 5 kW |

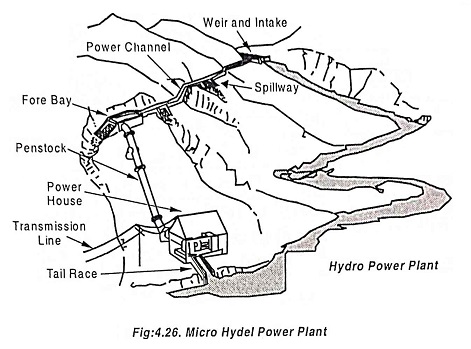

Components of Micro Hydel Power Plant:

The main components of micro hydro power plant are explained here.

- The water in the river diverted by the weir through an opening in the river side (the ‘intake’) into a channel.

- A settling basin is built into the channel to remove sand and silt from the water and this channel preserves the elevation of the diverted water.

- The channel directs the water in to a small reservoir/tank known as the ‘forebay’ from there it is directed to the turbines through a closed pipe known as the ‘penstock’.

- The penstock essentially directs the water to the turbine at a lower level.

- The turning shaft of the turbine can be used to rotate a mechanical device such as a grinding mill, wood lathe etc. directly, or to operate an electricity generator.

- The machines which are energized by the turbine are called the ‘load’.

- When electricity is generated, the ‘power house’ where the generator is located transfers the electricity to a step-up ‘transformer’ which is then transmitted to the grid sub-station or to the village/area where this electricity is to be used.

Power from a Micro Hydro Plant:

To know the power potential of water in a stream, it is necessary to know the flow quantity of water available from the stream (for power generation) and the available head.

The quantity of water available for power generation is the amount of water (in m3 or liters) which can be diverted through an intake into the pipeline (penstock) in a certain amount of time. This is normally expressed in cubic meters per second (m3/s) or in liters per second (I/s).

Head is the vertical difference in level (in meters) through which the water falls down.

The theoretical power (P) available from a given head of water is in exact proportion to the head and the quantity of water available.

P= Q x H x η x 9.81 Kilowatts (kW)

Where,

- P= Power at the generator terminal, in kilowatts (kW)

- H = The gross head from the pipeline intake to the tailwater in metres (m);

- Q = Flow in pipeline in cubic meters per second (m3/s)

- η = The efficiency of the plant, considering head loss in the pipeline and the efficiency of the turbine and generator, expressed by a decimal.

This available power will be converted by the hydro turbine in mechanical power.

Suitable conditions for Micro-hydro Power:

The best geographical areas for exploiting small-scale hydro power are those where there are steep rivers flowing all year round, for example, the hill areas of countries with high year-round rainfall or the great mountain ranges and their foothills, like the Andes and the Himalayas. Islands with moist marine climates,’ such as Caribbean Islands, Philippines and Indonesia are also suitable. Low-head turbines have been developed, for small-scale exploitation of rivers where there is a small head but sufficient flow to provide adequate power. To assess the suitability of a potential site, the hydrology of the site needs to be known and a site survey carried out, to determine actual flow and head data. Hydrological information can be taken from the meteorology or irrigation department usually run by the national government.

The site survey gives more detailed information of the site conditions to allow power calculation to be done and design work to begin. Flow data should be gathered over a period of at least one full year, so as to ascertain the fluctuation in river flow over the various seasons. There are many methods for carrying out flow and head measurements and these can be found in the relevant texts.

Turbines for Micro Hydro Power:

Turbine is the main piece of equipment in the micro hydel power plant scheme that converts energy of the falling water into the rotating shaft power. The selection of the most suitable turbine for any particular hydro site depends mainly on two of the site characteristics – head and flow available. All turbines have a power-speed characteristic. This means that they will operate most efficiently at a particular speed, head and flow combination. Thus the desired running speed of the generator or the devices being connected/loading on to the turbine also influence selection. Other important consideration is whether the turbine is expected to generate power at part-flow conditions.

The design speed of a turbine is largely determined by the head under which it operates.