Instrumentation System Block Diagram:

Instrumentation System – The measurement and control of physical conditions is very important in many industrial and consumer applications. For example, the operator may make necessary adjustments in the measurement of temperature or humidity inside a dairy or meat plant to maintain the product quality, or to produce a particular type of plastic, precise temperature control of the plastic furnace is needed.

A transducer is generally used at the measuring site to obtain the required information easily and safely. As explained earlier, a transducer is a device that converts one form of energy into another.

For example, when a strain gauge is subjected to pressure or force (physical energy), the resistance of the strain gauge changes (electrical energy), i.e. it converts mechanical energy into electrical energy. Actually, an instrumentation system is used to measure the output signal produced by the transducer and mostly used to control the physical condition producing the output signal.

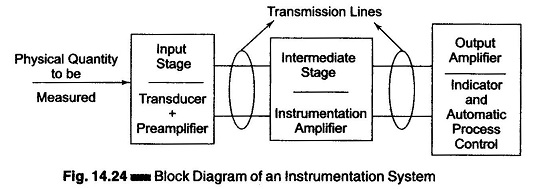

The simplified form of such an instrumentation system is shown in Fig. 14.24. This instrumentation system consists of a type of transducer as the input stage, depending upon the physical quantity to be measured. The transducers output is fed to the pre-amplifier. The instrumentation amplifier is the intermediate stage. The output of the instrumentation amplifier can be connected to various devices, such as meter, oscilloscope, charts or magnetic recorders.

Advanced technology has led to use of automatic instrumentation systems. This system have an automatic process controller used at the output stage, which compensates for changes in the operating condition.

The lines connecting the various stages, as shown in Fig. 14.24, are called the transmission lines. On the system requirement and the physical quantity to be monitored, the length of these transmission lines are chosen. These transmission lines permit signal transfer from unit to unit.

The output of the transducer is the input signal source of the instrumentation amplifier. A transducer which produces sufficient strength can be used to drive the output device directly. Most do not produce sufficient output. Hence, to amplify these low level output signals of the transducer instrumentation amplifiers are used which drive the indicator or display unit.

The instrumentation amplifier is required for precise low level signal amplification. In brief, they are used, where low noise, low thermal and time drift, high input resistance and accurate closed loop gain are required.