Interlocking Components in Electrical Drives

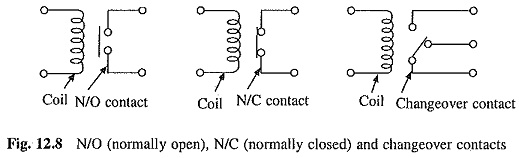

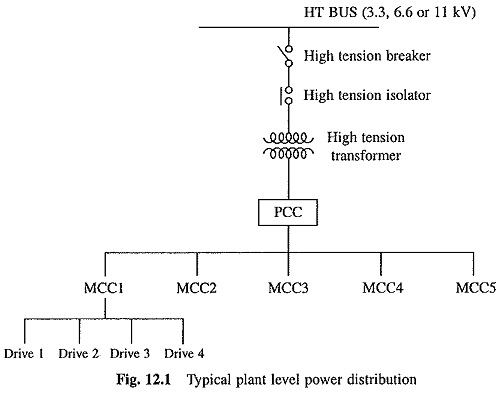

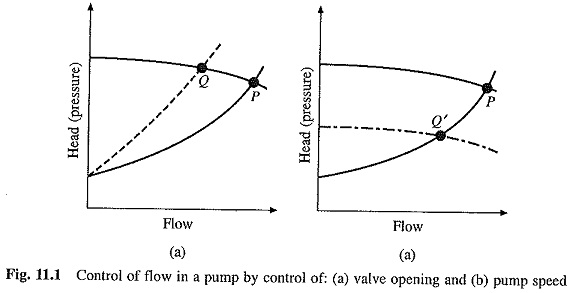

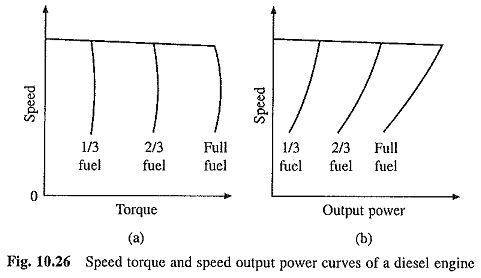

Interlocking Components in Electrical Drives: Sensing of signals required for speed and current control loops. Sequencing and interlocking operations are explained in the previous section, whereas this section discusses components used in interlocking and sequencing…