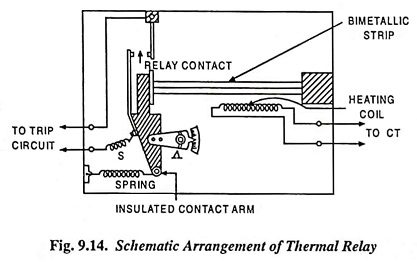

Thermal Relay Construction and Working Principle:

Thermal Relay can operate on the principle of thermal effect of electric current. It consists of bimetallic strips which are used in small sizes and are heated by heating coils or strips supplied through a current transformer. An insulated lever arm carrying a contact is pivoted and is held in contact with this trip with the help of spring S. The spring tension can be varied by rotating the sector shaped plate A. Under normal operating condition the strip remains straight but under the action of fault current the strip is heated and bent and the tension of the spring is released. Thus the relay contacts are closed which energises the trip circuit.

The construction of the bimetal element consists of two nickel alloyed steel strips, welded together. These strips have a high heat resistivity and are free from thermal secondary effects and ageing.

Applications:

These relays are mostly used for protection of low-voltage squirrel cage induction motors or dc motors of lower output ratings.

Limitations:

The limitation of such a relay is the short-time overload withstand. Its heating element is usually designed to withstand short-time overload say up to 6 or 7 times full-load current. The thermal relay is not suitable for operation on short circuit as it will burn the element sufficiently before the strip may deflect so as to close the contacts. This type of relay is used in conjunction with instantaneous short-circuit relays of high setting or suitably graded time limit fuses.