Benson Boiler – Construction, Working Principle and Advantages:

In 1927, Benson boiler was developed by Benson in West Germany. It was the first super critical drumless boiler.

Construction:

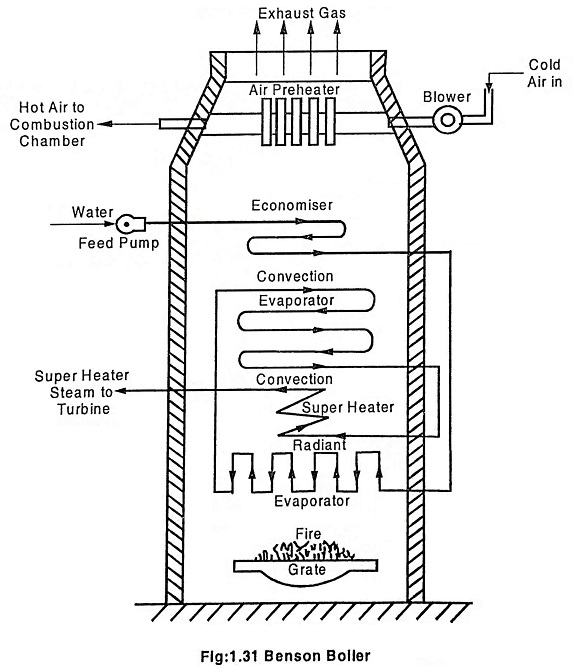

It is a high pressure, vertical, fire tube boiler. The Fig. 1.31 shows the schematic arrangement of a Benson boiler. This boiler has no drum and is designed to operate at critical pressure of 225 bar.

Working:

The fuel is burnt on the grate and the hot flue gases flow over radiant evaporator, convection super heater, convection evaporator, economizer and air preheater and then pass through chimney. The feed water is pumped through the economizer tubes and receives heat from the flue gases. Then this heated water flows into the radiant super heater where it receives further heat from the flue gases and gets evaporated. The remaining water is evaporated in the convection super heater. The steam now becomes saturated steam in the convection super heater. Then the steam is delivered out through the stop valve.

The water is passed to the radiant evaporator through the economizer. In the economizer, the major amount of water is converted into steam. The remaining water is evaporated in the final evaporator absorbing the heat from the hot gases by convection. The main disadvantage is salt deposition in this system in the transformation zone when all remaining water is converted into steam. To avoid this, for every 4000 hrs, after working periods, the boiler is cleaned by high pressure water. The maximum pressure obtained from Benson boiler is 500 atm.

Advantages:

- In this system, there is no drum. So the total weight of the Benson boiler is reduced by 20%, when compared to other boilers.

- The erection of this boiler is easier and quicker.

- Transformation is easy.

- It occupies very less space.

- It can be started very quickly, since it has welded joints.

- It is an economical one.

- Sudden fall of demand creates circulation problems due to bubble formation in the natural circulation boiler which never occurs in Benson boiler.

- Around only 4% of blow down losses are occurred in Benson boiler.

- There is no explosion hazards.