La Mont Boiler Construction and Working:

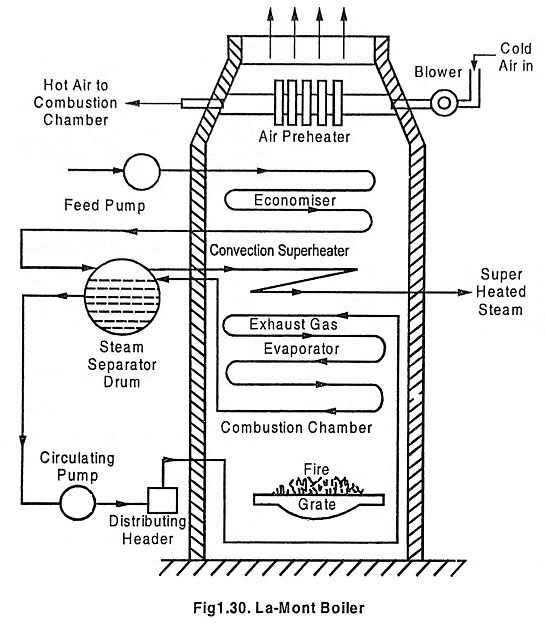

This type of boiler was introduced by Lamont in 1925. The arrangement of La Mont Boiler Construction and Working is shown in the Fig. 1.30.

It is a forced circulation, high pressure water tube boiler. The circulation of the water is maintained by a centrifugal pump. This pump is driven by a steam turbine using the steam from the boiler. In this La Mont Boiler, the separator drum is kept outside the boiler.

From the hot flue gases produced from the combustion of the fuel, the heat is supplied to the water in the evaporator tubes, super heater tubes, economizer tubes and the air in the air heater tubes; Then the waste gases move to the atmosphere through the chimney.

The separator drum separates the steam from water. Steam passes from the evaporator and feed water is fed from the economizer to the drum. The steam is separated from the water. The water is again pumped to the evaporator by the centrifugal pump via the distributing header. The separated steam is sent to the super heater which receives the heat from the flue gases flowing from the combustion chamber. This super heated steam is then delivered out through stop valve. An economizer is provided in the water circuit to preheat the feed water using the hot gases leaving the boiler.

The feed water is sent inside the boiler through the economizer. The centrifugal pump is used to circulate the water to the economizer. The centrifugal pump delivers the feed water to the headers at a pressure of 2.5 atm above the drum pressure. In evaporator, water is distributed through the nozzles.

The steam is going to the superheater before it goes to the prime mover. A choke is usually fitted at the entrance to each unit, in order to give a secure uniform flow of feed water through the pipe lines.

Capacity of boiler:

- Steam: 45 to 50 tons

- Pressure: 120 atm.

- Temperature: 500°C

Disadvantage of La Mont boiler:

The major disadvantage is the formation and attachment of bubbles on the inner surfaces of the heating tubes. This reduces the heat flow and steam generation.