Fluidized Bed Combustion Boiler Working and Types:

The coal available in India is of low quality, high ash content and low calorific value. The traditional grate fuel firing systems have got limitations and are techno-economically unviable to meet the challenges of future. Fluidized Bed Combustion Boiler has emerged as a viable alternative and has significant advantages over conventional firing system and offers multiple benefits -compact boiler design, fuel flexibility, higher combustion efficiency and reduced emission of noxious pollutants such as SOx and NOx. The fuels burnt in these boilers include coal, washery rejects, rice husk, bagasse & other agricultural wastes. The Fluidized Bed Combustion Boiler have a wide capacity range of 0.5 T/hr to over 100 T/hr.

When the high velocity gas is passed through a packed bed of finely divided solid particles, the particles become suspended in the gas stream and the packed bed becomes a fludised bed. When the gas velocity is very high, the fludised bed become turbulent and rapid mixing of particles occurs. Ultimately, the behavior of mixture of solid particles and gas become a fluid. Burning of a fuel in such a state is known as Fludised Bed Combustion. The boiler plant using this fludised bed combustion is known as fludised bed boilers.

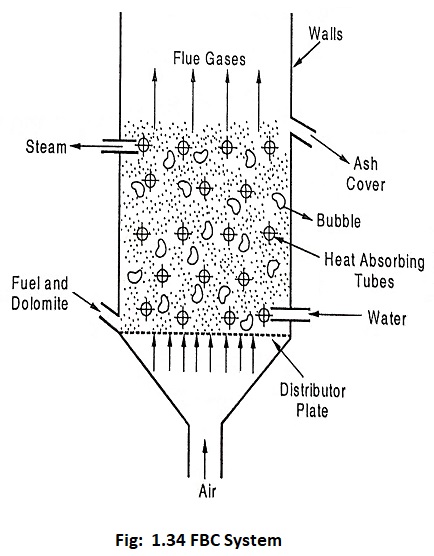

The Fluidized Bed Combustion Boiler system arrangement is shown in Fig.1.34.

At higher velocities, bubbles disappear, and particles are blown out of the bed. Therefore, some amounts of particles have to be recirculated to maintain a stable system – “circulating fluidised bed”.

Fluidization depends largely on the particle size and the air velocity. The mean solids velocity increases at a slower rate than does the gas velocity. The difference between the mean solid velocity and mean gas velocity is called as slip velocity. Maximum slip velocity between the solids and the gas is desirable for good heat transfer and intimate contact.

If sand particles in a fluidized state is heated to the ignition temperatures of coal, and coal is injected continuously into the bed, the coal will burn rapidly and bed attains a uniform temperature. The Fluidized Bed Combustion Boiler (FBC) take place at about 840°C to 950°C. Since this temperature is much below the ash fusion temperature, melting of ash and associated problems are avoided.

The lower combustion temperature is achieved because of high coefficient of heat transfer due to rapid mixing in the fluidized bed and effective extraction of heat from the bed through in-bed heat transfer tubes and walls of the bed. The gas velocity is maintained between minimum fluidisation velocity and particle entrainment velocity. This ensures stable operation of the bed and avoids particle entrailment in the gas stream.

The fuel and inert material dolomite are fed on a distributor plate and air is supplied from the bottom of the distributor plate. High velocity of air keeps the solid fuel in suspended condition during burning.

The heat is generated rapidly and transferred to the water passing through the tubes immersed in the bed and the steam is generated.

The inert material is used for controlling bed temperature. The heat generated by the combustion is first used for keeping up the temperature of the inert material and the balance is absorbed by the heat transfer surfaces. Sintered ash, fused alumina, sand, mullite and zirconia are some suggested inert materials for FBC.

Since the FBC system behaves like a violently boiling liquid, the heat transfer rate to the tube surface is quite high. Normally, 50% of the heat released in the bed is absorbed by the tubes immersed in the bed. Hence, the weight of the material and size of the boiler are considerably reduced.

Since the operating temperature of the bed is low and uniform, it prevents the fusion of coal ash and hence the ash produced is soft and less abrasive. The corrosion and erosion of submerged tubes are minimized as compared to conventional methods of combustion.

Since limestone is used as particle bed, control of SOx and NOx emission in the combustion chamber is achieved without any additional control equipment.

Conversion of Oil fired boilers to fluidized bed boilers:

Nowadays, oil fired boilers are slowly shifting to Fluidized Bed Combustion Boiler. For that, the following modifications are done.

- Furnace: Normally, oil fired boiler furnace is small in volume when compared to coal fired boiler furnace. Therefore, the furnace has to be suitably enlarged to retain the capacity. It requires high modification cost.

- Combustion system: To achieve complete combustion, excess air has to be supplied. The forced draft and induced draft fans provided for oil firing may not be suitable for coal firing needs. To get high flue gas velocity of 15 m/s, the existing forced draft fan has to be modified (or) replaced by high capacity fan for smooth running of FBC system.

- Air system: An air duct below distributor plate with approximate connection from forced draft fan is needed in FBC system. Hence special air ducting is needed.

- Flue gas system: The fly ash from FBC is soft due to low temperature. But high velocity excess air will lead to severe erosion. This unwanted erosion can be reduced by changing the gas path accordingly.

Types of Fluidized Bed Combustion Boiler system:

There are three types of fluidised bed combustion system, they are

- Bubbling fluidised bed combustion system

- Circulating fluidised bed combustion system

- Pressurised fluidised bed combustion system