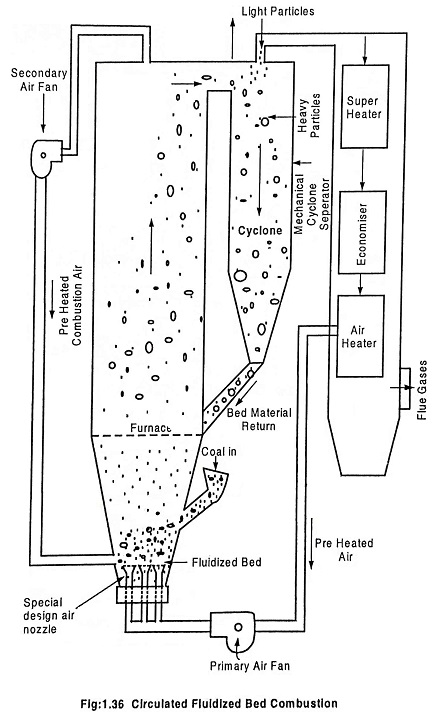

Circulating Fluidized Bed Combustion System (CFBC):

The Circulating Fluidized Bed Combustion System (CFBC) has evolved from conventional bubbling bed combustion to over come some of the drawbacks associated with bubbling bed combustion. CFBC provides greater flexibility in burning wide range of coal and other fuels without reduction in efficiency and with reduced pollution.

The Circulating Fluidized Bed Combustion System technology uses fluidised bed principle. The coal is crushed to 6 – 12 mm size and limestone is injected into the furnance (or) combustor. Since limestone is used as bed particle control of sulphur dioxide and nitrogen oxide emissions in the combustion chamber is achieved without any additional control equipment.

Special design of air nozzle is provided at the bottom of the bed which allows flow of air without clogging. Primary air fan provides the preheated fluidised air. Secondary air fan provides preheated combustion air. Nozzle in the furnance walls at various levels distribute the combustion air in the furnance.

There are no steam generation tubes immersed in the bed because circulating bed is designed to move a lot more solids out of the furnace area and to achieve most of the heat transfer outside the combustion zone (i.e) convection section. Some circulating bed boiler units have external heat exchangers.

Working:

When a preheated air supply is given at the bottom at high pressure, it lifts the bed material (limestone) and coal particles and keeps it in suspension. The coal combustion takes place at 840 – 900°C at this suspended condition, fine particles and partly burned coal ash and bed material are carried along with the flue gases to the upper areas of the furnace and then it passes through the mechanical cyclonic separator which separates light and heavy particles. The heavy particles are collected by mechanical cyclone separator and circulated back to furnance. Hence the name circulating fluidised bed combustion. The hot gases from the cyclone passes to the heat transfer surfaces and go out of boiler.

The particle circulation provides efficient heat transfer to the furnance walls and longer utilization time for carbon and limestone utilization.