Desert Cooler Construction and Working Principle:

As the name implies, it is suitable for places where the humidity is quite low and temperature quite high. Such conditions are in conformity with desert areas. Hence the coolers are called the desert coolers. The principle on which a desert cooler operates is “evaporative cooling“. Evaporative cooling is a process is which sensible heat is removed and moisture added to the air. When the air passes through a spray of water it gives up heat to water, some of water evaporates and picks up heat from the air equivalent to its latent heat. The vapours thus formed are carried along in air stream. In this way air is cooled and humidified.

Construction and Working:

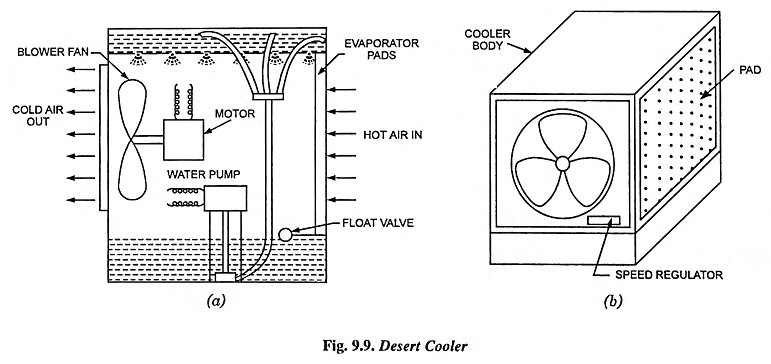

A desert cooler consists of the following main parts:

- Blower/Fan

- Water circulating pump

- Water wetted pads.

- Water tank

- Float valve

- Water traps.

The water is filled in the sump of the cooler from water supply mains, the level of which is controlled by a float valve. A water pump lifts the water and supplies it at the top of the cooler to the water distribution system which consists of small branches of copper pipe or so equipped with orifices which deliver equal amount of water to the troughs which in turn supply water to the wetted pads. The water which drops back from the pads is recirculated. The pump may be made of brass, stainless steel or even plastic.

The blower pulls the air through the wetted pads and delivers it to the space to be cooled through and opening in the fourth side of the desert cooler cabinet. The air sucked through the pads is cooled by the principle of evaporative cooling. The blower provides adequate velocity to the air before it is delivered to the space to be cooled.

To have long life of the desert coolers and better performance, pads should be changed every year and holes for water distribution system should be cleaned. The tank should be cleaned just after the season and coated with the corrosion resisting paint like red oxide and some other paints.

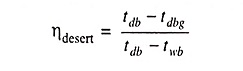

The efficiency of desert cooler is given as

where tdb is dry bulb temperature of ambient air, tdbg is the temperature of air leaving the grille, and twb is the wet bulb temperature of ambient air.

According to ISS, the velocity across the pads should be around 40 m/minute. The desert cooler efficiency should be about 75%. Though the high efficiency of desert cooler corresponds to cooled air, the large humidity causes discomfort. The desert cooler efficiency above 80% is not desirable. For good performance the efficiency of a desert cooler should not fall below 70%.