Auto Transformer Starter – Working Principle, Advantages and Disadvantages:

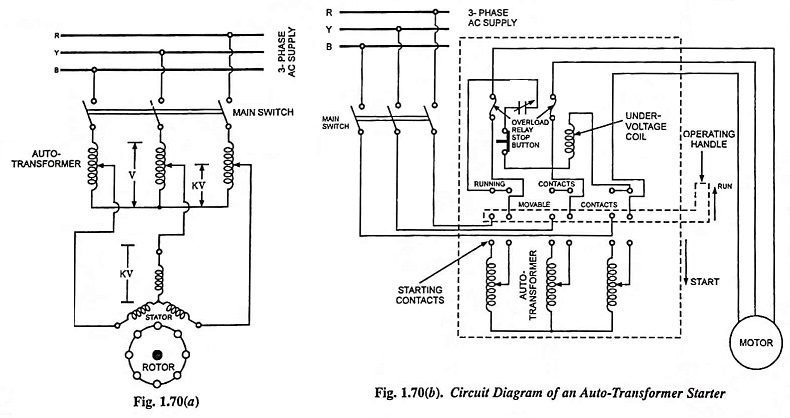

In auto transformer starter method the reduced voltage is obtained by taking tappings at suitable points from a three phase auto-transformer, as shown in Fig. 1.70(a). The auto-transformers are generally tapped at the 50, 60 and 80 per cent tapping points, so that adjustment at these voltages may be made for proper starting torque requirements. Since the contacts frequently break large values of current, arcing is sometimes quenched effectively by having them assembled to operate in an oil bath.

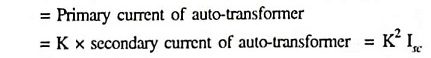

Auto transformer starter may be either manually or magnetically operated. The wiring diagram of an auto transformer starter is shown in Fig. 1.70(b).

Let the motor be started by an auto-transformer having transformation ratio, K. If Isc is the starting current when normal voltage is applied, and applied voltage to stator winding at starting = KV

then motor input current,

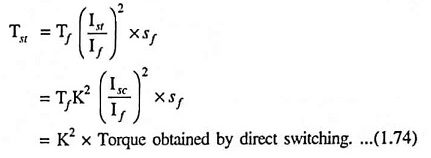

Supply current,

Starting torque,

Hence the line current and the starting torque are reduced in the square ratio.

Advantages:

The advantages of this method of starting of cage induction motors lies in the fact that the voltage is reduced by transformation and not by dropping the voltage in the resistors (or reactors) and, therefore, the current and power drawn from the supply mains are also reduced in comparison to primary resistor (or reactor) starting. The internal losses of the starter itself are small during long starting periods. Other advantages of this method are (i) availability of highest torque per ampere of supply current (ii) adjustment of starting voltage by selection of proper tap on the auto transformer starter (iii) suitability for long starting periods (iv) closed transition starting and (v) motor current larger than supply current.

Disadvantages:

The drawbacks of such starters are low power factor and higher cost in case of lower output rating motors.

This method can be employed for starting of star-connected as well as delta-connected motors.

For starting of large cage motors (of output rating exceeding 20 kW) this method of starting is often used.

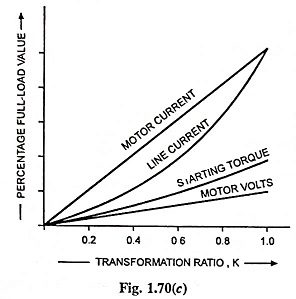

The aloes of starting torque available, together with the corresponding values of the voltage applied to the stator and the motor and line currents expressed as percentages of the normal full-load values, for different tap positions are shown in Fig. 1.70 (c).