PLC System Operation:

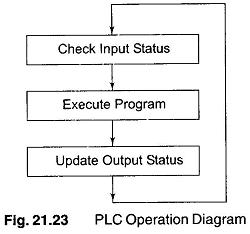

A PLC System Operation works by continually scanning a program. This scan cycle can be considered as made up of three important states as shown in Fig. 21.23. In addition there are also more than three states and these are used for checking the system and updating the internal counter and timer values.

The three important states are:

Step 1: Check Input Status: First the PLC takes a look at each input to determine if it is ON or OFF. In other words, it checks and senses whether the sensor connected to the first input is ON, to the second input is ON, to the third input is ON… It records this data into its memory to be used during the next step.

Step 2: Execute Program: The PLC System Operation next executes the program, one instruction at a time. For example, if the program says that if the first input was ON then it should turn ON the first output. Since it already knows which inputs are ON/ OFF from the previous step, it will be able to decide whether the first output should be turned ON based on the state of the first input. It will store the execution results for use later during the third step.

Step 3: Update Output Status: Finally the PLC updates the status of the outputs. It updates the outputs based on which inputs were ON during the first step and the results of executing the program during the second step. Based on example in step 2, it would now turn ON the first output because the first input was ON and the program said to turn ON the first output when this condition is true.

After the third step, the PLC System Operation goes back to step one and repeats the steps continuously.

The time taken to execute the above three steps or one instruction cycle is defined as the scan time.