Overfeed Stoker and Underfeed Stoker – Definition and Types:

There are two common methods used for burning coal.

1. Stoker firing 2. Pulverised fuel firing.

The stoker firing method is used for firing solid coal where as pulverised firing method is used for firing pulverised coal.

Stokers are generally used to fire solid fuels in the furnace. Stokers carry the fuel into the furnace for combustion. They discharge the combustion products to the appropriate place. The different types of stokers are:

- Over feed stokers

- Travelling grate stokers

- Spread stokers

- Under feed stokers

- Single retort stoker

- Multi retort stoker

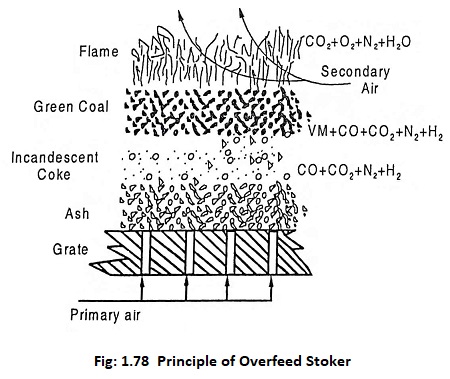

Overfeed stoker:

Combustion mechanism:

In overfeed stoker, the coal is fed on the grate above the entry point of the air. The primary air is forced through bottom of the grate by the forced draught fan. The air gets heated while it passes through grate openings and ash. Then it passes through a layer of incandescent (glowing with heat) cock, where the oxygen (O2) reacts with coke (carbon) to form carbon-di-oxide CO2. The water vapour in the air reacts with incandescent coke and forms carbon-di-oxide (CO2), carbon monoxide (CO) and free hydrogen (H2). The raw coal is continuously supplied over the fuel bed, the volatile matters are removed by the heat of the incandescent coke by distillation. The gases leaving the surface of the fuel bed are CO2, CO, N2, H2, H2O and combustible volatile matter. Secondary air is supplied over the surface of the fuel bed for burning the combustible gases. During incandescent, carbon in the fuel is lost by oxidation and only ash remains. The ash settles down at the bottom of the grate.

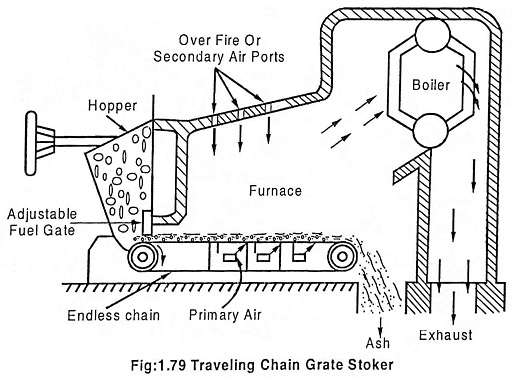

(a) Travelling grate stokers:

Travelling grate stoker is of two types 1. Travelling chain grate stoker and 2. Travelling bar grate stoker.

1. Travelling chain grate stoker:

In this type, the grate surface is made up of a series of cast iron links connected by pins to form an endless chain. This chain forms the fuel bed support. The chain travels over two sprocket wheels, one at the front of the furnace and another at the back. The front wheel is driven by a variable speed drive mechanism.

Working:

By gravity, the coal is fed to the travelling chain from the hopper. The depth of the fuel bed is adjusted by adjusting the fuel grate opening. According to the combustion, the speed of the chain is controlled.

Through the air inlets, the primary air required for combustion enters. The air duct under the grate is divided into sections to enable air supply to different ports of the stoker. The secondary air is supplied through the ports provided in the furnace walls. Both primary and secondary air supplied provides turbulence required for rapid combustion. The ash falls down at the rear end of the stoker and deposited in the ash pit.

Advantages:

- Simple in construction.

- Ash crusher is not required since no ash clinker is formed.

- Heat releasing rate can be controlled by adjusting the speed of the chain.

- Low initial cost and maintenance cost.

- High heat release per unit volume of the furnace.

Disadvantages:

- Since the amount of coal carried on the grate is less, this cannot be used for high capacity boilers.

- Some coal is lost in the form of fine particles with ashes.

- Pre heated air temperature is limited to 180°C

2. Travelling bar grate stoker:

Chain grate stoker and bar grate stoker differ only in construction. The grate surface of bar grate stoker is made up of a series of cast iron grate bars. The bar grate stoker is used to burn lignite and small size anthracite coal etc.

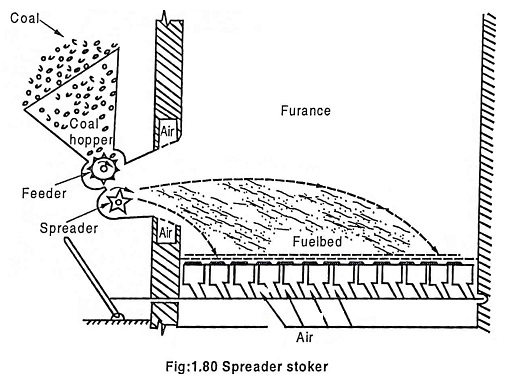

(b) Spreader stoker:

Spreader stoker consists of a hopper, feeder, spreader and openings for admitting air. In front of furnace wall, the coal feeding and distributing mechanism is located. The feeder is a rotating drum which consists of number of small blades. Spreader consists of a fast rotating shaft carrying twisted blades. Both travelling and stationary grates are used with spreader stoker.

Working:

By gravity, the coal is fed to the feeder from hopper. According to the combustion requirement, the feeder supplies the coal to the spreader.

The fast rotating blades of the spreader receives the coal particles coming from the feeder and distributes the coal uniformly over the grate. A part of coal is burnt in suspension and the remaining is burnt in the grate. Forced draught fan is used for supplying the required amount of air through grate openings.

Advantages:

- Wide variety of coal can be burnt easily.

- The clinkering problem is reduced by the spreading action.

- Flexible to load changes since most of the heat is released by burning coal in suspension.

- Fuel burns rapidly.

Disadvantages:

- An efficient dust collecting equipment is needed.

- It does not work satisfactorily for varying size of coal.

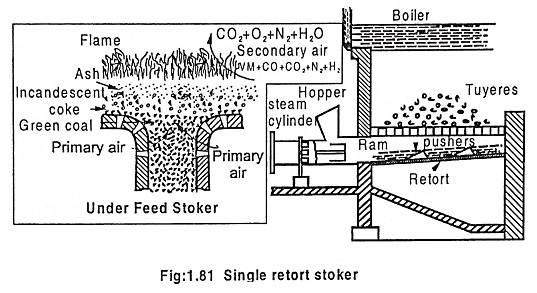

Under feed stokers:

In this type, both the fuel and air are fed from the bottom to the top in the same direction. The primary air passes through raw coal first. By the heat of incandescent fuel bed, combustible volatile matter is formed from the raw coal. The mixture of air and volatile matter passes through the ignition zone and then enters the incandescent coke. Hence the combustion process is highly efficient and gives high rate of heat release. The reactions that take place in incandescent coke is same as over feed stoker. Secondary air is supplied to burn the volatile matters.

(a) Single retort stoker:

This consists of a hopper, a cylinder fitted with ram, tuyeres for air and pushers.

The coal is fed into the cylinder by gravity. Then the coal is forced into the bottom of the horizontal trough by the reciprocating ram. The pushers push the coal into the grate. The air is supplied through tuyeres provided along the grate. The ash and clinkers are collected in the ash pit for removal.

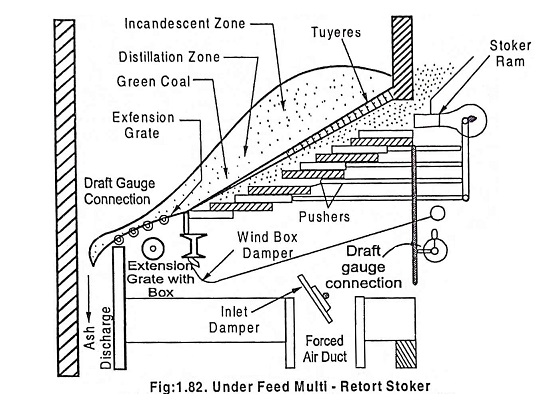

(b) Multi retort stoker:

Multi retort stoker consists of a series of alternate retorts and tuyere box. Each retort is fitted with pusher plate for uniform coal distribution. The coal is fed by gravity. This coal is pushed forward by the stoker ram. Then the pushers force the coal down to the entire stoker. Through tuyeres, the primary air is supplied. The ashes are collected at the lower end of the stoker.

Pulveriser:

To increase the surface exposure, the coal is pulverised. This enables rapid combustion. The pulverised coal is produced by grinding the raw coal in pulverizing mills. There are different types of pulverising mills namely 1. ball mill, 2. hammer mill and 3. bull and race mill

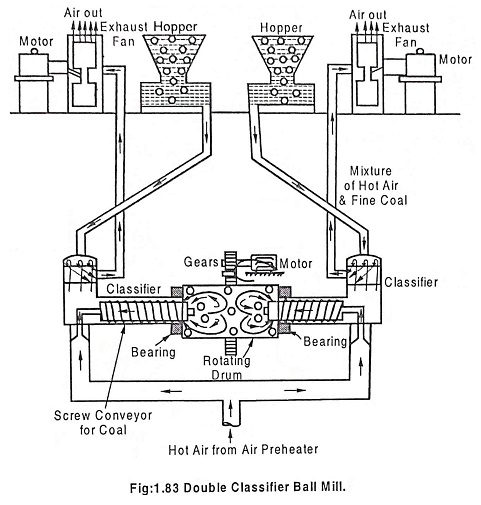

A ball mill consists of steel balls partly filled in a drum. The drum is rotated slowly. The raw coal is fed to the feeding hoppers. The coal moves to the drum through the classifiers and screw conveyors. As the drum rotates, there is a continuous impact between coal and the steel balls. Thus the coal is powdered. Hot air is passed through the drum. This air picks up the powdered coal with it. The coal air mixture enters the classifiers. In classifier oversized coal is returned back to the drum. The powdered coal and air mixture is drawn by the exhaust fan and supplied to the burners.

Pulverised fuel firing system:

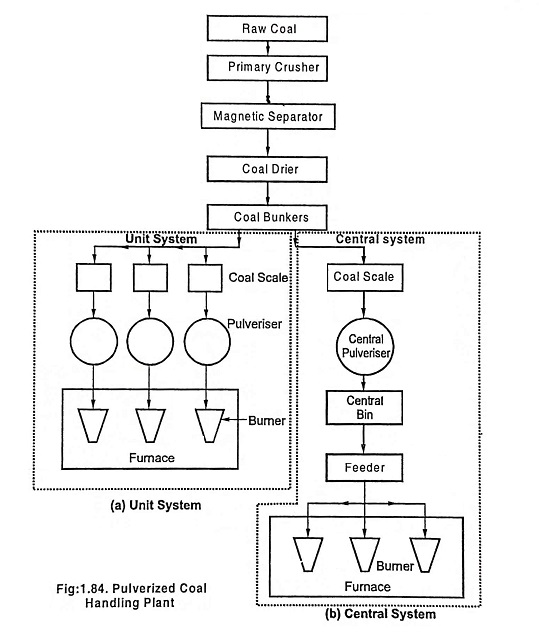

There are two methods of pulverised fuel firing system.

- Unit or direct system,

- Bin or central system.

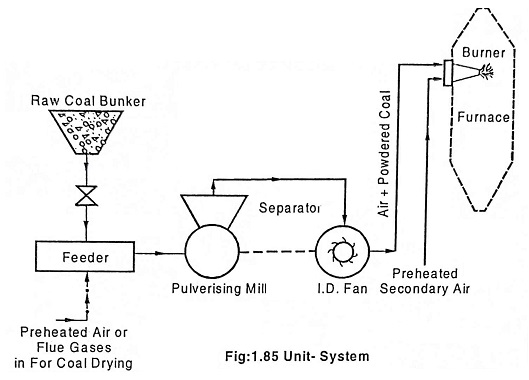

1. Unit (or) direct system:

A line diagram of unit system is given in the Fig.1.84(a) and 1.85.

The raw coal is supplied to the feeder from the coal bunker. Hot air (or) flue gas is passed through the feeder to dry the coal. The dried coal is fed into the pulverising mill and powdered. The induced draught fan brings primary air to the pulverising mill. This air carries coal with it and supplies to the burner through pipe. The secondary air is added in the burner before the fuel enters the combustion chamber.

Advantages:

- The layout is simple and economical.

- It gives direct control of combustion.

- Coal transportation system is simple.

- Maintenance cost is less.

Disadvantages:

- Power consumption is more at part loads by the poor performance of the pulverizing mill.

- Plant capacity is higher than central system.

- Fan blades are subjected to wear and tear excessively as they handle mixture of air & coal particles.

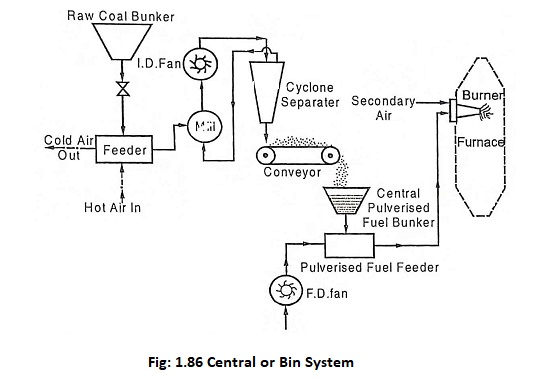

2. BIN (or) Central System:

A line diagram of bin system is shown in Fig.1.84(b) and 1.86. By gravity, the coal is supplied to the feeder or drier from the raw coal bunker. The coal is dried by passing hot gases, preheated air or bleeder steam. Then it is fed to the pulverising mill where it is pulverised.

An induced draught fan draws coal powder and air from the pulveriser and then it is passed through cyclone separator where air is separated from coal. The separated coal is transferred to the central fuel bunker (bin) by the conveyor system. Then the powdered coal enters the feeder. A forced draught fan supplies primary air into the feeder and the mixture of air and powdered coal is supplied to the burner.

Advantages:

- More flexible system changes can be made according to the demand.

- Quantity of fuel & air can be controlled separately.

- Break down in the coal supply will not affect the functioning of the boiler for some time.

- Less power consumption.

- Less labour requirement.

- Burner operation is independent of coal preparation.

- Sometimes the pulveriser can be made idle, if there is sufficient fuel in bunker.

Disadvantages:

- Capital coal is high.

- Space requirement is more.

- Driers must be used.

- There is possibility of fire hazard of stored pulveriser.

- Coal transportation system is more complicated.

- Operational and maintenance cost is high.