Current Collection System in Electric Traction and Types of Current Collection:

There are mainly two systems of current collection system for locomotives, tramways or trolley buses viz

- Conductor rail system and

- Overhead system.

Current collection from overhead system is far superior to that from the conductor rail system. This is because both theoretically and experimentally current collection system is more difficult from a rigid body than from an elastic one. Further the insulation of the third rail at high voltages used on single phase ac traction would also be impracticable and endanger the safety of the personnel.

1. Conductor Rail System:

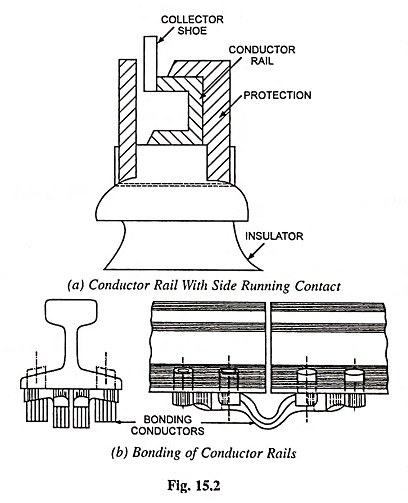

conductor rail system is employed at 600 V for suburban services on account of its relative cheapness and easier inspection and maintenance. The supporting structure does not interfere in the visibility of the signals. Also, it is not necessary to protect the rail from accidental contact by plate players etc., except at stations and in sidings. In this system, current is supplied to the electrical operated vehicle either through one rail conductor or through two rail conductors. In case of one rail conductor the track rail is employed as the return conductor. The advantage of using insulated return rail is elimination of electrolytic action due to return currents on other public services buried in the vicinity of the railway tunnels. The rails are mounted on insulators parallel with the track rails at a distance of 0.3 to 0.4 m from the running rail with their upper most surface acting as contact surface and are fed at suitable points from substations. Conductor rail with a side running contact, as shown in Fig. 15.2 (a), is also employed. Some railways employ an under-running contact. Latter systems are supposed to be more protective against accidental contact. The wearing of the rail conductor is due only to the friction of the collector shoes and pitting which usually occurs at starting when the current drawn is very large. The rails are designed from electrical considerations rather than mechanical.

The main considerations are

- electrical conductivity,

- cost,

- wearing qualities,

- contact surface available for the collector shoes and

- shape and size of the conductor rail, keeping in view the type of insulators used.

A special steel alloy is used for the rails for economy reasons. The composition is such that it provides high conductivity and at the same time satisfies all other requirements. A typical composition is iron 99.63%, carbon 0.05%, manganese 0.2%, phosphorous 0.05%, silicon 0.02% and sulphur 0.05%. It has a resistance of about 12.0 x 10-8 Ω-m at 18°C (about seven times of that of copper and about one quarter or one-fifth of that of the running rails). To reduce the voltage drop at joints, conductor rails are bonded together by short length flexible copper conductors riveted or welded to the rails. The conductor rail is not fixed rigidly to the insulators in order to take care of the contraction and expansion of rails. To prevent creepage due to friction of the collector shoes, however, it is anchored at intervals of 100 to 150 metres.

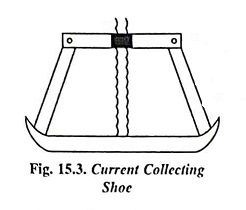

The current is conveyed from the conductor rail to the train equipment by means of collector shoe (flat steel shoe about 20 cm in length and 7.6 cm in width) which presses on to the rail with a force of about 15 kg. In case of top contact the necessary contact force is obtained by gravity and in case of side and under-running contacts springs are employed to obtain necessary contact force. The current which can be collected is about 300 to 500 A. Sometimes it may not be convenient to have the conductor rail on the same side of the track, therefore, it is desirable to provide shoes on both sides of the locomotive or train. Also, there are going to be gaps in the rails at points and crossings, at least two shoes must be provided on each side so as to avoid discontinuity in the current flow. This system is suitable for heavy current collection, top contact system for voltage up to 750 V and side contact system up to 1,200 V.

2. Overhead System:

This Overhead system is adopted when the trains are to be supplied at high voltage (1,500 volts or above). In this system with high operating voltage the trains requiring high power may be supplied through conductors of relatively small cross section and the collection of the current required by a train can be done by a collector with a sliding contact. Overhead construction is universal for all ac railways and is also used with dc tramways, trolley buses and locomotives operating at voltages of 1,500 volts and above. In all these cases the running rails are utilized as the return conductor, therefore, with dc and single phase system only one overhead wire is required for each track.