Gases and Gas Mixtures for Insulation Purposes:

Over the years, considerable amount of work has been done to adopt a specific gas for practical use. Before adopting a particular gas or gas mixtures for a practical purpose, it is useful to gain a knowledge of what the gas does, what its composition is, and what the factors are that influence its performance. The greater the versatility of the operating performance demanded from an insulating gas or gas mixtures, the more rigorous would be the requirements which it should meet. These requirements needed by a good dielectric do not exist in a majority of the gases.

Generally, the preferred properties of a gaseous dielectric for high voltage applications are:

- high dielectric strength,

- thermal stability and chemical inactivity towards materials of construction;

- non-flammability and physiological inertness, and environmentally nonhazardous,

- low temperature of condensation,

- good heat transfer, and

- ready availability at moderate cost.

Sulphur hexafluoride (SF6) which has received much study over the years has been found to possess most of the above requirements.

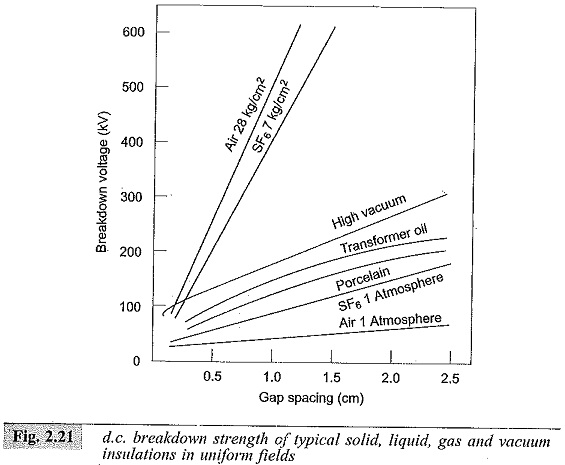

Of the above properties, dielectric strength is the most important property of a gaseous dielectric for practical use. The dielectric strength of gases is comparable with those of solid and liquid dielectrics (see Fig. 2.21).

It is clear that SF6 has high dielectric strength and low liquefaction temperature, and it can be used over a wide range of operating conditions. SF6 was also found to have excellent arc-quenching properties. Therefore, it is widely used as an insulating as well as arc-quenching medium in high voltage apparatus such as high voltage cables, current and voltage transformers, circuit-breakers and metal enclosed substations.

SF6 and Other Gas Mixtures:

SF6 is widely used for applications in power system due to its high dielectric strength and good arc interruption properties. However, SF6 gas has been found to be a green house gas that causes environmental problems. The production and use of SF6 gas has increased steadily and today it is about 10,000 metric tons due to leakages into the atmosphere from the electrical equipment. The concentration of SF6 in the environment has been steadily increasing. The release of SF6 into the atmosphere leads to concentration of large volumes of SF6 gas in the upper atmosphere. SF6 molecules absorb energy from the sun and radiate it into the atmosphere for long duration of time.

There has been a large concern for these environmental effects and therefore the electrical industry has been looking for an alternate gas or gas mixtures to be used in electrical equipment which presently use SF6 gas, as an insulating and arc interruption medium. The large amount of experimental data that is presently available suggest that 40% SF6/60% N2 mixtures have all the dielectric characteristics that make it suitable for use as insulation in high voltage equipment. Ideally the gas mixtures should be suitable for use in the existing equipment as well as in the equipment that will be designed and manufactured in future.

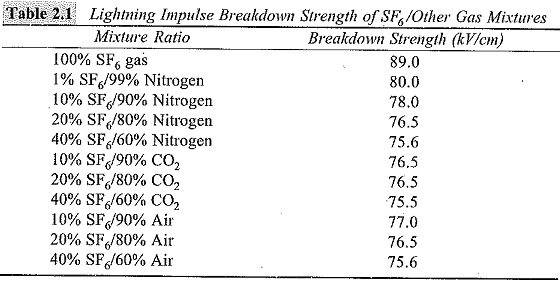

Extensive research work done in SF6 and its mixtures with N2 , air and CO2 has given breakdown values which are 80-90% of the pure SF6 values as shown in Table 2.1.

The industry is looking for a gas mixtures that can replace the pure SF6 gas in the existing SF6 insulated apparatus, requiring no change in hardware, test procedures or ratings. SF6/N2 mixture is the one that has been found to be a good replacement for SF6. SF6/N2 mixtures have been used in Gas Insulated Transmission System and were found to perform well. Also, the work done so far has shown that the ability of SF6/N2 mixtures to quench high current arcs is promising. The cost of such mixtures is low and are less sensitive to field non-uniformities present inside the equipment. In view of the above, the industry is trying to find out the optimum mixture ratio and the total pressure of the SF6/N2 mixture that would be required for a variety of applications. For many applications, such as Gas Insulated Transmission Systems, cables, capacitors, current transformers and, voltage transformers, mixtures with different SF6 concentrations varying from 5% to 40%.

SF6/N2 mixtures show promise as a medium in circuit breakers. It has been found that a mixture containing 69% SF6/3 1% N2 gave higher recovery rate than pure SF6 at the same partial pressure. It has also been shown that it is possible to further improve the arc interruption properties of SF6 by using SF6/N2 or SF6/He mixtures.

In summary, it may be said that there is an urgent need to significantly reduce the use of SF6 gas and its leakage from power apparatus. Use of gas mixtures appears to be feasible, but it has to be ensured that there is no loss in the performance of the equipment. Therefore, further research has to be carried out to identify a suitable gas mixture, its pressure and its arc interruption capability to be used in the existing apparatus and the apparatus that will be designed and manufactured in future.