Electron Beam Welding – Working Principle, Advantages, Disadvantages and Applications:

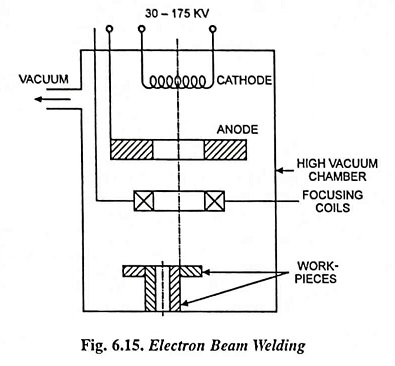

Basically, electron beam welding in vacuum utilises the kinetic energy of electrons travelling with high velocity in a high vacuum (10-3 to 10-5 mm Hg). When the electrons strike the surface of the metal, they give up the bulk of their energy as heat, and this goes to melt the metal. If the work is done in a high vacuum, no electrodes, gases, or filler metals need contaminate it and pure welds can be made. Moreover, high vacuum is necessary around the filament so that it will not burn up and will also produce and focus a stable beam (Fig. 6.15).

In all types of electron beam machines, a tungsten filament which serves as a cathode emits a mass of electrons that are accelerated and focused to a 0.25-1 mm diameter beam of high energy density up to 0.5-10 kW/mm2. The temperature produced is about 2.500°C. This is sufficient to melt and vaporize the work-piece material and thus fills a narrow weld gap even without a filler rod (although filler rods may be employed).

The speed of the beam is stepped to one-half to two-third of the speed of light by passing it through a high-voltage electrostatic field. An electromagnetic lens is used to obtain correct focusing of the beam.

A similar process, known as non-vacuum electron beam welding is rapidly coming into use today, i.e., many welds are now made without elaborate arrangement required for vacuum electron beam welding. In this case, the vacuum chamber in which the beam is created is evacuated to a lower pressure. In situation where contamination of the workpiece must be held to a minimum, the beam should be passed through argon or helium. To make the chamber high vacuum, it takes about 5 to 30 minutes to evacuate the air, depending on the size of the chamber. A medium size electron beam welder operates below 60 kV. The welding head or the work is moved by numerical control or by hand.

The advantages of electron beam welding are that the welds are clean, with no porosity since there is no air ; no shielding gas is required ; and as the energy input is in a narrow, concentrated beam, distortion is almost eliminated. The speed may be as fast as 2,500 mm per minute, and it will weld or cut any metal or ceramic, diamond, sometimes as thick as 150 mm.

Advantages:

The major advantage of electron beam welding is its tremendous penetration, which occurs when the highly accelerated election hits the base metal. It will penetrate slightly below the surface and at that point release the hulk of its kinetic energy, which turns to heat energy. This brings about a tremendous temperature rise at the point of impact. The succession of electrons striking the same place causes melting and then evaporation of the base metal. This creates metal vapours, but the electron beam travels through the vapour much easier than solid metal. This causes the beam to penetrate deeper. The depth-to-width ratio can exceed 20 : 1. With the increase in power density, penetration is increased. Penetration also depends on the beam current. With the increase in beam current, penetration is increased. The other variable, travel speed, also affects penetration. As travel speed is increased, penetration is reduced.

Since the electron beam has tremendous penetrating characteristics, with the lower heat input, the heat affected zone is much smaller than of any arc welding process. In addition, because of almost parallel sides of the weld nugget, distortion is greatly reduced. The cooling rate is much higher, and for many metals this is advantageous; however, for high carbon steel this is a drawback and cracking may occur.

Almost all metals can be welded with the electron beam welding process. The metals that are most often welded are super-alloys, the refractory metals, the reactive metals, and the stainless steels. Many combinations of dissimilar metals can also be welded.

Disadvantages:

One of the disadvantages of the electron beam process is its high capital cost. The price of equipment is very high, and it is expensive to operate, due to the requirement for vacuum pumps. In addition, fitup must be precise and locating the parts with respect to the beam must be perfect.

Applications of Electron Beam Welding:

Today automobile, airplane, aeroscape, farm and other types of equipments including ball-bearing over 100 mm are being welded by the electron beam process.