DC Motor Braking Methods:

The need for electric braking was explained earlier, the motor works as a generator developing a negative torque which opposes the motion. Three types of DC Motor Braking Methods are

- Regenerative braking;

- Dynamic or Rheostatic braking; and

- Plugging or reverse voltage braking.

1. Regenerative Braking:

In regenerative braking, generated energy is supplied to the source.

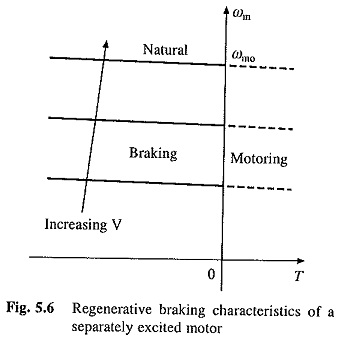

Field flux cannot be increased substantially beyond rated because of saturation. Therefore, according to Eqs. (5.1) and (5.15), for a source of fixed voltage of rated value regenerative braking is possible only for speeds higher than rated and with a variable voltage source it is also possible below rated speeds. The speed-torque characteristics can be calculated are shown in Fig. 5.6 for a separately excited motor. In series motor as speed increases, armature current, and therefore, flux decreases. Consequently, condition of Eq. (5.15) cannot be achieved. Thus regenerative braking is not possible.

In actual supply system when the machine regenerates its terminal voltage rises. Consequently the regenerated power flows into the loads connected to the supply and the source is relieved from supplying this much amount of power. The regenerative braking is therefore possible only when there are loads connected to the line and they are in need of power more are equal to the regenerated power. When the capacity of the loads is less than the regenerated power, all the regenerated power will not be absorbed by the loads. The remaining power will be supplied to capacitors (including stray capacitances) in line and the line voltage will rise to dangerous values leading to insulation breakdown. Hence, regenerative braking should only be used when there are enough loads to absorb the regenerated power. Alternatively an arrangement is made to divert the excess power to a resistance bank where it is dissipated as heat. Such a braking is known as Composite Braking because it is a combination of regenerative braking and dynamic braking. When the source is a battery, the regenerated energy can be stored in the battery.

2. Dynamic Braking:

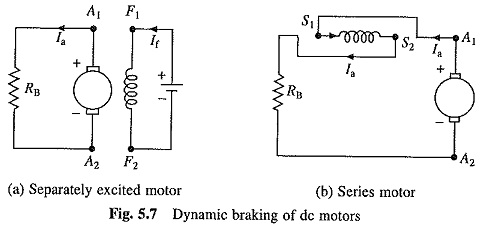

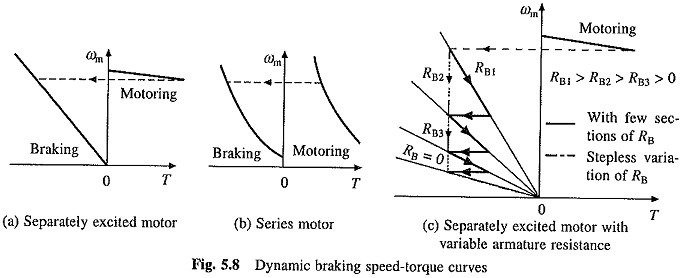

In dynamic braking, motor armature is disconnected from the source and connected across a resistance RB. The generated energy is dissipated in RB and Ra. The braking connections are shown in Fig. 5.7(a) and (b). Since series machine works as a self-excited generator, the field connection is reversed so that field assists the residual magnetism. Figures 5.8(a) and (b) show speed-torque curves and transition from motoring to braking. These characteristics are obtained for V = 0. When fast braking is desired, RB consists of a few sections. As the speed falls, sections are cut-out to maintain a high average torque, as shown in Fig. 5.8(c) for a separately excited motor.

During braking, separately excited motor can be converted as a self-excited generator. This permits braking even when supply fails.

3. Plugging:

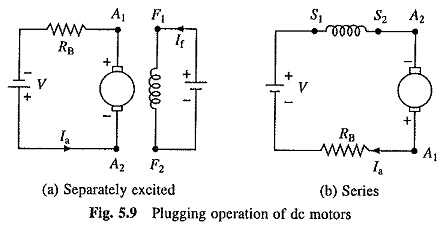

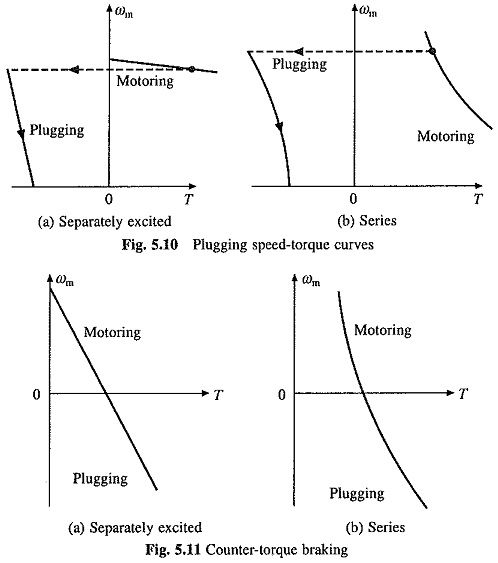

For plugging, the supply voltage of a separately excited motor is reversed so that it assists the back emf in forcing armature current in reverse direction (Fig. 5.9). A resistance RB is also connected in series with armature to limit the current. For plugging of a series motor armature alone is reversed. Speed Torque curves can be calculated by replacing V by -V and are shown in Fig. 5.10. A particular case of plugging for motor rotation in reverse direction arises, when a motor connected for forward motoring, is driven by an active load in the reverse direction. Here again back emf and applied voltage act in the same direction. However, the direction of torque remains positive (Fig. 5.11). This type of situation arises in crane and hoist applications and the braking is then called Counter Torque Braking.

Plugging gives fast braking due to high average torque, even with one section of braking resistance RB. Since torque is not zero at zero speed, when used for stopping a load, the supply must be disconnected when close to zero speed. Centrifugal switches are employed to disconnect the supply. Plugging is highly inefficient because in addition to the generated power, the power supplied by the source is also wasted in resistances.