Starting of Squirrel Cage Induction Motor:

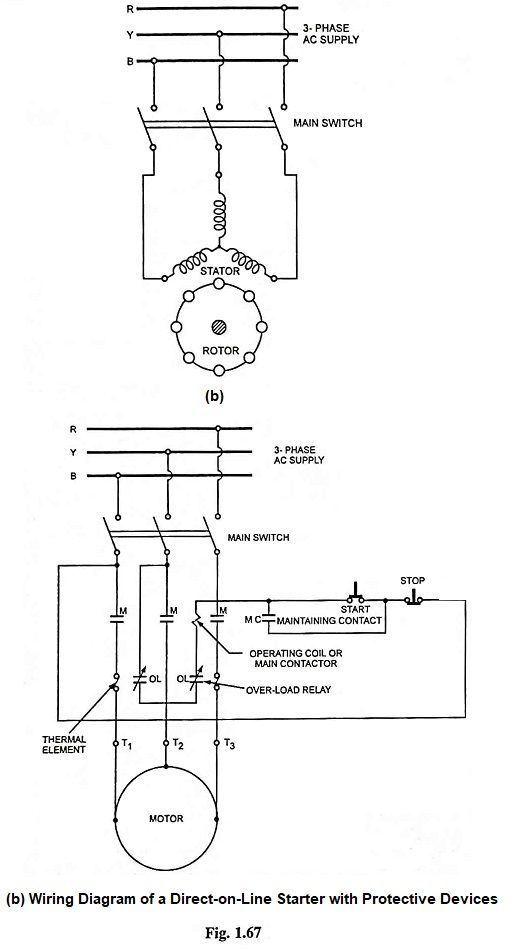

Direct-on-Line Starting or Full-Voltage Starting – As already mentioned, squirrel-cage induction motors, as a general rule, up to 4 or 5 kW are started by this method. As the name suggests, this starting of squirrel cage induction motor method involves direct switching of polyphase squirrel cage induction motor to supply mains, as illustrated in Fig. 1.67(a).

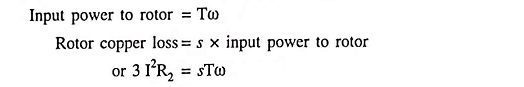

The push-button type direct-on-line starter, which is very common in use, is shown in Fig. 1.67(b). It is simple, inexpensive and easy to install and maintain. It consists of a set of ‘start’ and ‘stop’ push buttons, a contactor (an electromagnet) with its associated contacts and usually overload and under-voltage protection devices. The start button is momentary contact that is held normally open by a spring. The stop button is held normally closed by a spring. Thermal overload relays are commonly used for motor overload protection.

Under-voltage protection is provided by the contactor (that is controlled by a three-wire control circuit) maintains the interruption of circuit even after the supply is restored.

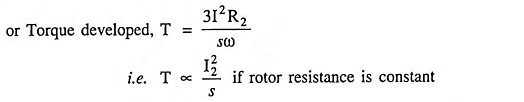

Torque Developed on Starting of Squirrel Cage Induction Motor By Direct Switching:

where I2 is the rotor current per phase, R2 is rotor resistance per phase, T is the torque developed, s is the slip and ω is the supply angular velocity.

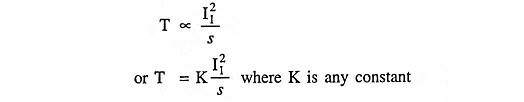

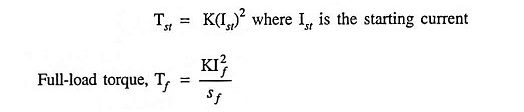

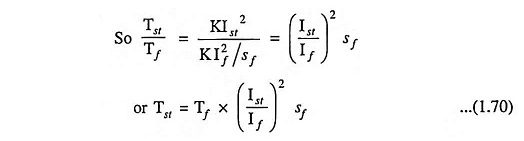

Since rotor current is proportional to stator current I1, so

At starting slip, s = 1

So starting torque,

where If is the full-load motor current and sf is the full-load slip

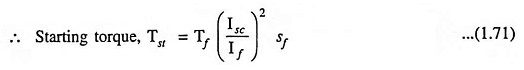

When the motor is connected directly across the supply mains, the starting current is equal to the short-circuit current, Isc