Power Sources for Welding Process:

Both dc and ac are used for electric arc welding, each having its particular applications; in some cases either is suitable. The electric properties of the arc determines the requirements that should be met by source of power supply for arc welding. To initiate an arc, a higher voltage is required than to maintain it under normal conditions. For this reason the open-circuit voltage of the power sources for welding (when there is no arc drawn between the electrode and the work) must be higher than the arc, or closed-circuit voltage (when there is an arc drawn between the electrode and the work).

With dc the open-circuit voltage must be at least 30 or 35 volts, while with ac it should be not lower than 50 or 55 V. An open arc will be sustained at 18 to 25 volts. Open-circuit voltage usually ranges from 50 to 90 volts.

To initiate an arc, the electrode is touched to the work and is then withdrawn a short distance. On contact, the electrode shorts the welding circuit and an inadvertent short circuit may give rise to an excessive current in the circuit, which may dangerously heat and even burn the insulation. A power sources for welding should, therefore, be able to limit the surge of current, when the arc is initiated, to a small percentage above the desired value.

In metal arc welding the globules of molten electrode metal are carried across the arc, thus changing the resistance of the arc and consequently the arc voltage and current. In fact the arc resistance is continually varying within broad limits in very short periods of time. The point is that the molten globules of metal pass from the electrode to the plate at the rate of 30 or more per second, continually causing approximate short circuits from the electrode to the work. If the arc is not to go out, the power sources for welding must be able to quickly vary its voltage with the resistance of the arc.

Of special importance is the ability of a power supply source to restore the voltage quickly after a globule of molten metal has broken away from the electrode. The arc will only restrike at not less than 25 volts. The voltage should, therefore, recover to 25 volts within 0.05 second.

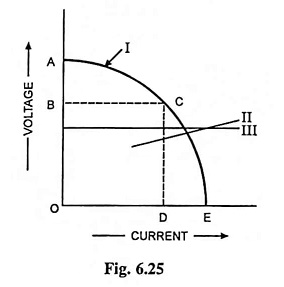

For manual welding with coated electrodes the static characteristic (curve giving relation between the source voltage and the welding current) is represented by curve I in Fig. 6.25. This is a drooping or negative characteristic. OA represents the open-circuit voltage, OB represents the arc or closed circuit voltage, OD represents the arc current and OE represents the short-circuit current. The point C on the curve I shows the instant of striking the arc. With this type of volt-ampere characteristic the short-circuit current in the welding circuit is reduced to a limit safe enough for the windings of the welding generator or transformer.

If the arc has a flat (curve III) or a rising volt-ampere characteristic (curve II) such as in shielded arc welding, automatic welding with large currents the power sources for welding should also have a flat or a rising characteristic respectively.

To sum up, the power supply for manual arc welding should meet the following requirements :

- The open-circuit voltage must be sufficient for an arc to strike without difficulty, but safe for the operator (below 80 volts).

- The short-circuit current must be within limits of safety for generator or transformer windings.

- The voltage of the source of power supply should vary rapidly with changes in arc length.

- The wattage of the source of power supply should be sufficient to give the desired arc current.