Current Collector for Overhead System and Types of Current collector in traction:

The current in the overhead system is collected with the help of sliding contact collector mounted on the roof of the vehicle. The main requirement of a current collector is that it should, under no circumstances, leave the contact of overhead equipment. Contact wire in all practical installations is never perfectly horizontal, it rises and falls depending upon the weight of the contact wire, and distance between droppers. Also contact wire comes very low under bridges and tunnels and rises high over public crossings. The current collector for overhead system has to rise and come down according to the speed of the electric vehicle in order to maintain the contact with overhead equipment.

Therefore, in order that the current collector gear picks up the current without any spark, it must be designed so as to maintain an even pressure against the trolley wire at all speeds. To ensure an even pressure the current collector gear must have a sufficient flexibility to adjust itself to the variation of the level of the conductor at high speeds. Either a spring or compressed air is used to maintain the pressure. When the contact wire rises the current collector has to move upwards so as to maintain contact, and the pressure exerted on the contact wire is the pressure of the spring or compressed-air piston less the force required to accelerate the current collector to its new position and any force necessary to overcome the frictional resistance. To design a satisfactory current collector for overhead system therefore, particularly for high speed work, the frictional resistance must be reduced to a minimum and the moment of inertia must be kept low. Furthermore, means must be provided for lowering when idle and reasonable precautions taken to prevent the collector leaving the wire at points and crossings.

As the tramcars and trolley buses draw their power from overhead conductors suspended about 6.7 m (from 4.7 m to 7.5 m) above the road surface, the current collector must, therefore, be mounted on the vehicle.

Types of Current collectors in traction:

Three types of current collectors are in common use, viz,

- Trolley collector,

- Bow collector and

- Pantograph collector.

1. Trolley Collector:

The trolley collector is universally employed with tramways and trolley buses. This consists of a grooved gun metal wheel or grooved slider shoe with carbon insert carried at the end of a long pole. The other end of this pole is hinged to a swivelling base fixed to the roof of the vehicle. Necessary upward pressure for the pole and current collector for overhead system is achieved by means of springs. As two trolley wires are required for a trolley bus a separate trolley collector is provided for each wire, the bases being mounted side by side. The pressure for wheel is approximately 10 kg and for a carbon insert slider is approximately 17 kg.

Advantages:

The main drawback of trolley collector is that it has to be rotated through 180° for reversing the direction of motion of the vehicle. Another drawback particularly with trolley wheel collector is that there is poor contact between the wheel and trolley wire. This gives rise to high current density in gassy mines where trolley collector with grooved slider shoe is preferred.

The trolley collector is suitable for comparative low speeds (say 24 to 32 kmph) beyond this speed there is every possibility of its jumping off the trolley wire.

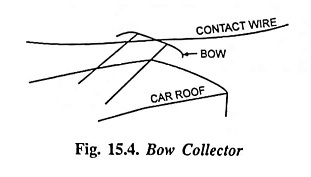

2. Bow Collector:

The bow collector is also employed for collecting the current with tramways. The bow collector consists of light metal strip or bow 0.6 or 0.9 metre wide pressing against the trolley wire and attached to a framework mounted on the roof of vehicle. Although provision of metal strip enables vehicle to run at higher speeds without running the risk of leaving the contact of trolley wire, its manoeuvrability is lost. It is as such not suitable for trolley buses. In order to avoid jumping off of the trolley wire at high speeds, it is desired that the wire be accurately located above the track and staggered about 15 cm to each side of centre line to avoid the wearing of the groove in the contact strip. Collection strip is made of soft material such as copper, aluminium or carbon so that it should wear instead of trolley wire as it is easy to replace worn out collection strip than trolley wire.

Necessary upward pressure is obtained by springs. The length of the poles is kept sufficient to have lateral movement along the mean path of trolley bus. This arrangement enables vehicle to run at higher speed without danger of the jumping off wire. Bow collector has always to run trailing just like trolley collector. It, therefore, requires either provision of duplicate bows or an arrangement of reversing the bows for motion in the reverse direction. The bow collector has smaller inertia but is not so readily adoptable for collection of large currents as is a pantograph collector.

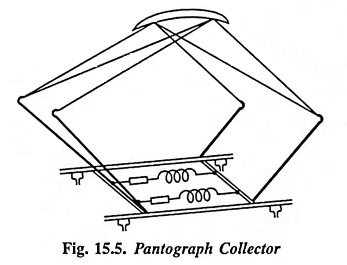

3. Pantograph Collector.

The pantograph is employed in railways for collection of current where the operating speed is as high as 100 or 130 kmph and the currents to be collected are as large as 2,000 or 3,000 amperes. Pantographs are mounted on the roof of the vehicles and usually carry a sliding shoe for contact with the overhead trolley wire. These consist of a jointed frame usually of steel tubing. The contact shoes are usually about 1.2 metres long. There may be a single shoe or two shoes on each pantograph. The shoes may be straight throughout their lengths or cambered slightly or may be in the form of an auxiliary bow. Material used for pantograph is often steel with sometimes, wearing plates of copper or bronze inserted. The pressure varies from 5 to 15 kg.

The pantograph is raised or lowered from the driver cab by one of the following methods or with some modification of it.

- air raised, gravity lowered.

- air raised, spring lowered.

- spring raised, air lowered.

The pantographs should be of such construction that they maintain continuous contact with the overhead wire at reasonably constant pressure at any height. They must be light enough in order to follow the overhead wire as it changes height above the rails to pass under overhead crossing etc., with minimum inertia effects even at high speeds they must be sufficiently strong and rigid to resist air pressures both head on, due to speed of train, and transverse, due to wind; also they must resist stresses due to the sway of the locomotive at high speeds and to some extent, stresses due to blows from the overhead system at deflectors or turnouts etc. and from striking birds. If, however, there is a serious trouble on the overhead system, the pantograph must be sufficiently pliable so that it will be damaged rather than pulling down the overhead structure.

The above arrangement has the following advantages over other types of collectors.

- It can operate in either direction of motion.

- There is no risk of leaving wire junction etc.

- The erection of the overhead network is very simple due to absence of points and grooved crossings required for bows.

- Its height can be varied from the drivers’ cabin by carrying out simple operations.