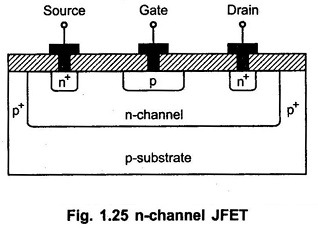

Types of Field Effect Transistor

Types of Field Effect Transistor: In general, Three Types of Field Effect Transistor are namely, Junction field effect transistor (JFET) Metal oxide semiconductor field effect transistor (MOSFET) Complementary Metal Oxide Semiconductor (CMOS) Junction field effect…