Van De Graaff Generator Working Principle:

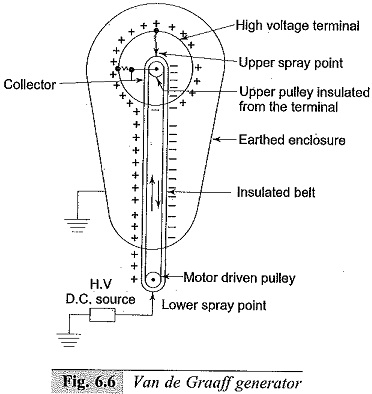

The schematic diagram of a Van De Graaff Generator Working Principle is shown in Fig. 6.6. The generator is usually enclosed in an earthed metallic cylindrical vessel and is operated under pressure or in vacuum. Charge is sprayed onto an insulating moving belt from corona points at a potential of 10 to 100 kV above earth and is removed and collected from the belt connected too–the inside of an insulated metal electrode through which the belt moves. The belt is driven by an electric motor at a speed of 1000 to 2000 metres per minute. The potential of the high voltage electrode above the earth at any instant is V= Q/C. where Q is the charge stored and C is the capacitance of the high voltage electrode to earth. The potential of the high voltage electrode rises at a rate

where I is the net charging current.

A steady potential will be attained by the high voltage electrode when the leakage currents and the load current are equal to the charging current. The shape of the high voltage electrode is so made with re-entrant edges as to avoid high surface field gradients, corona and other local discharges. The shape of the electrode is nearly spherical.

The charging of the belt is done by the lower spray points which are sharp needles and connected to a d.c. source of about 10 to 100 kV, so that the corona is maintained between the moving belt and the needles. The charge from the corona points is collected by the collecting needles from the belt and is transferred on to the high voltage electrode as the belt enters into the high voltage electrode.

The belt returns with the charge dropped, and fresh charge is sprayed onto it as it passes through the lower corona point. Usually in order to make the charging more effective and to utilize the return path of the belt for charging purposes, a self-inducing arrangement or a second corona point system excited by a rectifier inside the high voltage terminal is employed.

To obtain a self-charging system, the upper pulley is connected to the collector needle and is therefore maintained at a potential higher than that of the high voltage terminal. Thus a second row of corona points connected to the inside of the high voltage terminal and directed towards the pulley above its point of entry into the terminal leaves an excess of opposite polarity to the terminal to travel down with the belt to the bottom charging point. Thus, for a given belt speed the rate of charging is doubled.

The charging current for unit surface area of the belt is given by I = bν δ, where b is the breadth of the belt in metres, ν is the velocity of the belt in m/sec, and δ is the surface charge density in coulombs/m2. It is found that δ is ≤ 1.4 x 10-5C/m2 to have a safe electric field intensity normal to the surface. With b = 3 m and ν = 3 m/sec, the charging current will be approximately 125 μA. The generator is normally worked in a high pressure gaseous medium, the pressure ranging from 5 to 15 atm. The gas may be nitrogen, air, air-freon (CC12F2) mixture, or sulphur hexafluoride (SF6).

Van De Graaff Generator Working Principle are useful for very high voltage and low current applications. The output voltage is easily controlled by controlling the corona source voltage and the rate of charging. The voltage can be stabilized to 0.01%. These are extremely flexible and precise machines for voltage control.