Cranes and Hoist Drives:

The Requirements of the Cranes and Hoist Drives are

- The motion of the crane hook is in all three dimensions.

- In crane drives, the acceleration and retardation must be uniform. This is more important than the speed control.

- For exact positioning of the load creep speeds must be possible.

- When the motion is in the horizontal direction braking is not a problem. This is a problem if the load overhauls the motor in vertical motion. In the case of vertical motion the movement of the empty cage has to be carefully The speed must be constant while lowering the loads. The steady braking of the motor against cnierhauling must be possible.

- The drive must have high speeds in both the directions. The motor must have high speeds at light loads.

- Mechanical braking must be available under emergency conditions.

- Power lowering may be used when an empty cage or light hooks are

The duty cycle of cranes depends upon some requirements. These are:

- it must be able to perform strenuous duty

- it must withstand high ambient temperature

- it must be able to work in a dusty atmosphere

- it must provide trouble free operation

- it should have rigid safety measures.

Cranes and Hoist Drives are classified depending upon the nature of duty they have to perform and also the duty cycle.

These are light duty, medium duty, heavy duty and continuous duty

Drive Motors for Cranes and Hoist Drives

The crane motors can be either dc or ac motors.

Even though the electrical characteristics make dc motors suitable as crane motors, the lower inertia and simple and economical construction of cage motors favour them as crane motors. With the advent of thyristors and associated power converters it is possible to have torque control during starting, running and braking.

DC Systems for Cranes and Hoist Drives

Speed control is achieved by means of Ward Leonard system with all facilities of speed control in forward and backward directions with regeneration.

Among the dc motors, series motors are extremely suitable for crane operation. They have the following features:

- They have very good starting torque, high torque capability at low speeds and light torques at high speeds.

- Power demand under highly loaded conditions decreases due to, fall in

- Electrical braking is possible even at low speeds due to low critical speeds.

- Very light conditions are not possible. Suitable changes may be made in the circuitry to make it to run at low speeds and light load conditions.

- The lowering speeds increase with the load. Regenerative braking is not possible to limit this speed. The speed of the empty cage can be limited by limiting the current to full load value.

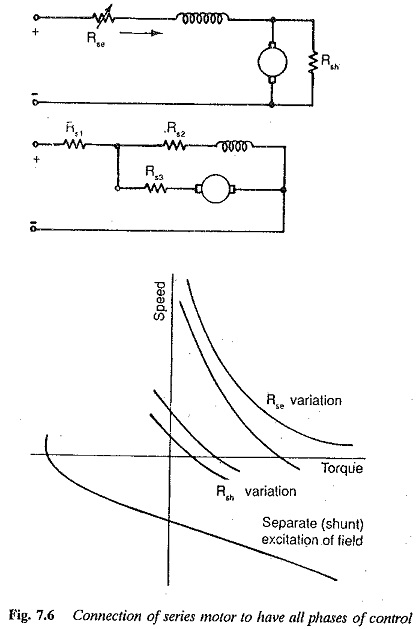

However, the speed-torque characteristics of dc series motors may be modified to suit all the phases of crane control, and are depicted in Fig. 7.6.

AC Systems for Cranes:

Among ac motors, squirrel cage motors are normally used. They have the following features:

- No speed control is required. However with the development of variable frequency converters which solve the problems of speed control of induction motor, inverter fed motors are used in situations requiring wide range of speed control.

- They have fast acceleration and a fixed sequence of operation.

- Regenerative braking is not a problem. This occurs automatically when the load overhauls or the empty cage is being raised.

- The Motor is simple and robust

These are not suitable when a large number of starlings and brakings are required. A starting torque up to 250% of full load torque may be obtained. In cases of very high starting torque these are not suitable. Non-uniform sequence of operation cannot be handled and conventional methods of speed control are not suitable if precise speed control is necessary.

Slip ring induction motors for cranes and hoists have the following features:

1. The speed-torque curve can be modified by suitably altering the rotor resistance. The starting torque can also be varied to the required value.

Regeneration is possible. Reverse current braking can be employed limiting the current to the desired value by rotor resistance. DC dynamic braking may also be employed. While selecting a motor for crane duty the following points require consideration:

- Breakdown torque must be greater than 250% (in the range of 275-300)

- The inertia must be small.

- It must withstand large frequency of starts.

- The motor must have sufficient running torque, starting torque and thermal capability for the given duty cycle.

- The duty cycle must be specified.