Underground Cables Interview Questions and Answers:

1. For what purpose metallic sheath is provided in underground cables ?

Ans. The metallic sheath is provided around the insulation to protect it against ingress of moisture, gas or other damaging liquids (acid or alkalies) from the soil and atmosphere.

2. Why is a layer of bedding provided over the metallic sheath in underground cables ?

Ans. A layer of bedding is provided over the metallic sheath for the protection of metallic sheath against corrosion and from mechanical injury.

3. Why are copper conductors not used in power cables ?

Ans. Copper conductors are not used in power cables because of scarcity of copper.

4. What are the main requirements of insulating materials used for underground cables ?

Ans. The main requirements of the insulating materials used for underground cables are high insulation resistivity, high dielectric strength, good mechanical properties, non-hygroscopic, non-inflammable, immune to attacks by acids and alkalies.

5. Why VIR cables preferred over paper cables for smaller installations ?

Ans. VIR cables are preferred over paper cables for smaller installations as they are smaller in size, stronger, durable and economical.

6. Why single-core cables are usually not provided with armouring ?

Ans. Single-core cables are usually not provided with armouring in order to avoid excessive loss in the armour.

7. Give classification of underground cables.

Ans. According to voltage, the cables may be classified as:

- Low voltage (LT) cables for operating voltage up to 1,000 V.

- High voltage (HT) cables for operating voltage up to 11,000 V.

- Super-tension (ST) cables for operating voltage up to 33,000 V.

- Extra high tension (EHT) cables for operating voltage up to 66,000 V.

- Extra super-voltage cables for operating voltage beyond 1,32,000 V.

A cable may be a single-core or multi-core depending upon the type of service for which it is intended to be used. A multi-core cable may be two-core, three-core or four-core. For 3-phase, 3-wire systems either three single-core cables or three-core cables can be used depending upon the operating voltage and load demand. For 3-phase, 4-wire systems 4-core cables may be used.

8. List three groups of underground cables used.

Ans. The underground cables may be grouped into three groups as (i) lt cables, (ii) ht cables and (iii) EHT cables.

9. What are voids ?

Ans. Empty spaces in cables are called voids. The formation of voids in cables causes unequal voltage stresses (which may exceed the safe limits) and also temperature rise due to leakance current.

10. How void formation can be eliminated in cables ?

Ans. In EHT and super-voltage cables useful for 132 kV and above, the formation of voids are eliminated by increasing the pressure of compound in it.

11. Give the limitations of 3-core belted type cable.

Ans. The belted type construction is not suitable for the cables used for voltages above 22 kV because of development of both the radial and tangential stresses. The tangential stresses act along the layers of insulation. The electric resistance, therefore, dielectric strength of the impregnated paper is much higher across the layers than along the layers. The leakage current on account of tangential stresses along the impregnated paper insulation causes power loss at the centre filling and local heating resulting in breakdown at any moment. Further owing to non-homogenity of dielectric in belted construction, when cables are loaded and unloaded some portions of the dielectric are less stressed whereas some portions are overstressed resulting in formation of vacuous spaces and voids. These vacuous spaces are ionised when voltage is applied and ultimately deteriorate the cable insulation.

12. On what factors does the insulation resistance of a cable depend ?

Ans. The insulation resistance of a cable depends upon core radius, insulation thickness, length of cable and resistivity of insulating material.

13. How does the insulation resistance of a cable vary with its length ?

Ans. Insulation resistance of a cable varies inversely as the length of the cable.

14. Write the expression of insulation resistance of a single-core cable.

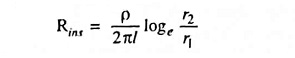

Ans. Insulation resistance of a single-core cable is given by expression

where ρ is the resistivity of the insulating material, l is the length of cables and r1 and r2 are radii of cable conductor and internal sheath respectively.

15. On what factors does the capacitance of a single core depend ?

Ans. The capacitance of a single core depends upon its length, relative permittivity of its dielectric and the ratio of core diameter to sheath inner diameter.

16. How does electric stress vary in the dielectric of a cable ?

Ans. The electric stress in the dielectric of a cable varies inversely as the distance from the centre of the cable and hence minimum at the sheath and maximum at the conductor surface.

17. For what value of R/r the minimum value of stress is obtained in a cable ?

Ans. For value of R/r = e i.e., 2.71828 the minimum value of stress is obtained in a cable.

18. What do you understand by the term grading of cables ?

Ans. The process of achieving uniformity in dielectric stress is known as grading of cables.

19. What is meant by capacitance grading of cables ?

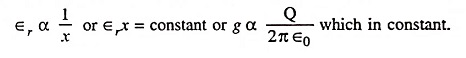

Ans. In the capacitance grading of cables, the uniformity in dielectric stress is achieved by using various layers of different dielectrics in such a manner that the permittivity, ∈r of any layer is inversely proportional to its radius of distance from the centre i.e.,

20. What is the modern practice adopted to avoid grading of cables ?

Ans. The modern practice adopted to avoid grading of cables is to employ oil-filled or gas-pressure cables.

21. Name the sources of heat generation in cables.

Ans. Within the cables the sources of heat generation are

- I2R losses in the conductor.

- Dielectric losses in the cable insulation.

- Losses in the metallic sheath and armourings.

22. Why loss angle of a cable should be very small ?

Ans. As the dielectric losses occurring in a cable are very small, the value of loss angle δ is small.

23. How does dielectric loss vary with the change in voltage, frequency of supply and capacitance of cable ?

Ans. The dielectric loss in a cable varies in proportion with the capacitance of a cable and frequency of supply and varies as the square of the voltage.

24. Mention important factors to be considered while selecting a cable.

Ans. The factors to be considered in selection of a cable are continuous current rating, voltage grade, permissible voltage drop and short-circuit current rating (in case of ht cables only) and operating cost.

25. What is the cause of underground cable failure ?

Ans.

- The most common point of failure is at the cable sealing box mostly due to poor workmanship of the cable jointer when the end was sealed. Damage caused to the insulation on account of improper handling at the time of laying will also ultimately result in a failure.

- Another very common cause is the mechanical puncturing of the lead sheathing of a cable, such as by a crowbar, especially in industrial installations where excavation and building operations are carried on in areas having several underground cables.

- Although the lead sheathing of underground cables has a very high degree of resistance against corrosion, but inspite of it certain soils are chemically active and may cause severe pitting and corrosion.

- The cable may also get damaged due to vibration fatigue or overheating.

- Where a cable is laid vertically up posts, or walls, the impregnating oil is likely to leak from the cable box at the lower level due to the hydrostatic pressure.