Types of Auto Reclosing:

Types of Auto Reclosing can be broadly classified in two categories:

- Medium voltage auto-reclose where continuity of supply is the principal aim.

- High voltage auto-reclose where the main considerations are of stability and synchronizing.

Medium Voltage Auto-Reclose:

The obvious advantages are continuous supply except for short duration when tripping and reclosure operations are being performed, this renders the substation unattended. The success of rapid reclosure to a large extent depends on the speed of operation of the protections. This is so because high speed protection decreases the amount of damage incurred and thus increases the probability of successful operation of reclosing, consequently it renders the system less vulnerable to any fault which may occur later. In some cases application of automatic reclosing enables us to use very simple but high speed protections of the lines. With instantaneous protection being applied indiscriminate tripping of several circuit breakers is possible but the provision of this Types of Auto Reclosing makes it a selective operation. The principles of acceleration of the overcurrent protections by means of automatic reclosing is discussed below.

(i) Overcurrent Protection with Acceleration Prior to Automatic Reclosure:

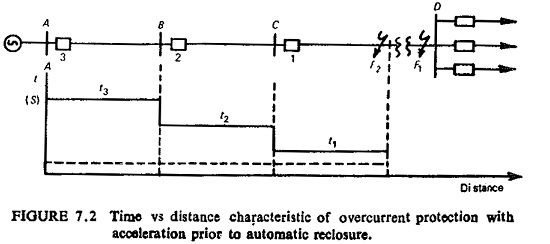

In this case the provision of single shot auto-reclosure in a nonselective overcurrent high speed protection makes the protection selective. Consider the system shown in Fig. (7.2). Overcurrent protection with time delays located at breakers 1, 2 and 3 are provided so that t1<t2<t3. The nonselective high speed overcurrent protection and automatic reclosure is located at breaker 3 only. The pickup current of this high speed protection is selected so that it only responds for faults occurring on the line sections AB, BC and on that part of section CD before the transformer bank. Therefore, for faults within the protected zone the high speed overcurrent protection trips breaker 3. After this the automatic reclosure immediately returns the line to service and at the same time the high speed overcurrent protection is removed for a time a little more than the operating time of overcurrent time delay relay (t3) located at breaker 3, i.e. tout > t3. This is necessary because if the fault persists after the reclosure, it should be cleared by overcurrent protections at 1, 2 or 3. The advantage is that only one automatic reclosing system on the head section of the line is required. Simplicity of the scheme for short distribution systems where the intermediate substations are not suited for automatic reclosing is an attractive feature of this scheme.

(ii) Overcurrent Protection with Acceleration after the Automatic Reclosure:

In this case the fault is first cleared by overcurrent protection with stepped time delays. After this, automatic reclosure returns the line to service and if the fault is permanent, the high speed overcurrent protection operates and removes the line from service.

(iii) Overcurrent Protection with In turn Automatic Reclosure:

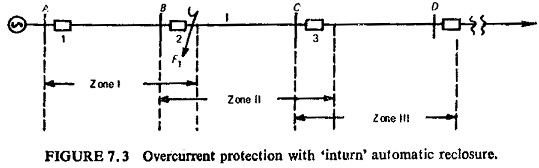

It enables us to realize high-speed protection of every section against transient as well as permanent faults. This is achieved by installing high speed nonselective overcurrent protections at all head parts of the sections. The pickup value for all such protections is selected for faults inside the full length of the given section and not for faults beyond the stepdown transformers if one such exists. Different zones of protection are shown in Fig. (7.3). Any nonselective operation of faults outside the given section is corrected by this Types of Auto Reclosing. When the line is protected by composite overcurrent protection, the first stage of the protection can he employed as high speed nonselective overcurrent protection.

Consider a permanent fault at F1 of system shown in Fig. (7.3). The high speed relays of breakers 1 and 2 will operate. Practically immediately the automatic recloser located at breaker 1 restores the section 1 to service. As the fault F1 is located outside section 1 and breaker 2 is still open the high speed overcurrent protection of section 1 will not operate, although it was automatically removed from service for a little while. Now after a time delay tAR2 the automatic recloser at breaker 2 closes.

where

tAR2 = time delay of the automatic recloser at breaker 2.

tAR1 = inherent time delay of the automatic recloser at breaker 1.

ΔtAR = time step ≈ 0.5 second.

As the fault of F1 is permanent, the high speed overcurrent protection of section 2 opens breaker 2 once more and removes section 2 from service. This scheme has increasing clearing times as we proceed towards the far end of the line.

High Voltage Auto-Reclose:

In the high voltage circuits where the fault levels associated are extremely high, it is essential that the system dead time be kept to a few cycles so that the generators do not drift apart. High speed protection such as pilot wire carrier or distance must be used to obtain operating times of One or two cycles. It is therefore desired that the reclosure be of the single shot type. High speed reclosure in high voltage circuits improves the stability to a considerable extent on single-circuit ties. On double circuit ties subjected to single circuit faults the continuity through the healthy circuit prevents the generators from drifting apart so fast and increase in the stability limit is thus moderate. Nevertheless, it is sometimes important. However, when the faults occur simultaneously on both the circuits the stability limit increases again considerably.

The successful application of high speed auto-reclose to high voltage systems interlinking a number of sources depends on the following factors.

- The maximum time available for opening and closing the circuit breakers at each end of the faulty line, without loss of synchronism.

- The time required to deionize the arc at the fault, so that it will not restrike when the breakers are reclosed.

- The speed of operation on opening and closing of the circuit breakers.

- The probability of transient faults, that will allow high speed reclosure of the faulty lines.

It will be seen that some of these conditions are conflicting, e.g. the faster the breakers are reclosed the greater the power that can be transmitted without loss of synchronism, provided that the arc does not restrike. But here the likelihood of arc restriking is greater. An unsuccessful reclosure is more detrimental to stability than no reclosure at all. For this reason the time allowed to deionize the line must not be less than the critical time for which the arc hardly ever restrikes. The reduction of reclosing time obtained by high speed relaying is however preferred as it reduces the duration of arc. Indeed, the increase in power limit due to reclosing is much greater with very rapid fault clearing than with slower fault clearing, For best results the circuit breakers at both ends of the faulty line must be opened simultaneously. Any time during which one circuit breaker is open in advance of the other represents an effective reduction of the breaker electrical dead time and may well jeopardize the chances of a successful reclosure.

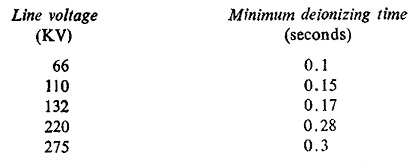

To determine the electrical dead time for a circuit breaker used in a high speed auto-reclose scheme it is essential to know the time interval during which the line must be kept deenergized in order to allow for the complete deionization of the arc and ensure that it will not restrike when the line is reconnected to the system. The deionization time of an arc in open atmosphere depends on a number of factors such as: circuit voltage, conductor spacing or gap length, fault current, fault duration, wind velocity, etc.

Line voltage is the most important of all the factors affecting the arc deionization time. Typical values of deionization times for an arc in free air are